Focus on spectral sensing and optoelectronic application systems

Industrial In-Line LIBS System

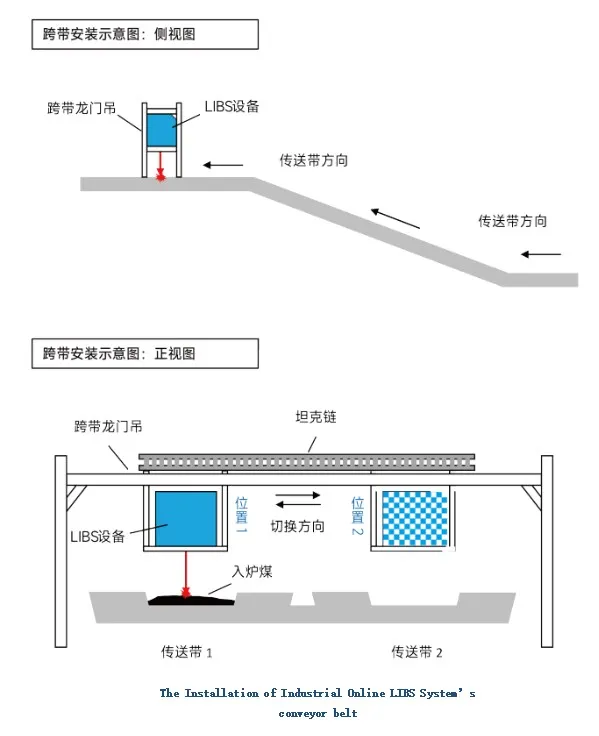

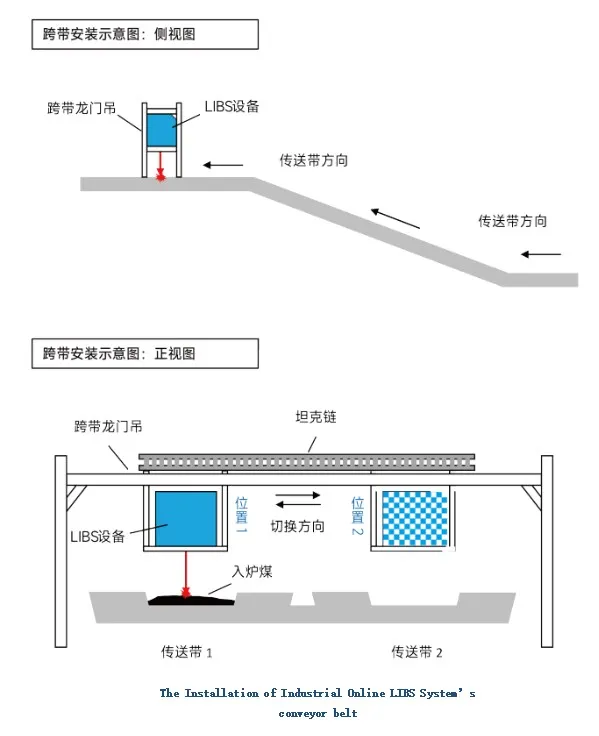

The iSpec-LIBS-IND industrial online LIBS (Laser Induced Breakdown Spectroscopy) system from LiSen Optics is a customizable solution designed to meet specific user requirements and application scenarios. For example, it can use multiple-channel high-resolution spectrometers for synchronous data collection; the system features an integrated cabinet design that is dustproof, shockproof, and corrosion-resistant, suitable for hanging over conveyor belts, and capable of real-time display of device status and measurement results. It adapts to different environmental temperature changes.

The iSpec-LIBS-IND industrial online LIBS (Laser Induced Breakdown Spectroscopy) system from LiSen Optics is a customizable solution designed to meet specific user requirements and application scenarios. For example, it can use multiple-channel high-resolution spectrometers for synchronous data collection; the system features an integrated cabinet design that is dustproof, shockproof, and corrosion-resistant, suitable for hanging over conveyor belts, and capable of real-time display of device status and measurement results. It adapts to different environmental temperature changes.

Product Introduction

iSpec-LIBS-IND

The principle

The principle of Laser Induced Breakdown Spectroscopy (LIBS) involves using high-intensity lasers to excite and eject a few micrograms of material from the surface of the sample. This process, often termed laser ablation, simultaneously produces a plasma with a very short lifespan but high brightness, reaching temperatures of up to 10,000℃. In this hot plasma, the ejected material dissociates into excited atoms and ions. After the laser pulse ends, the plasma cools rapidly as it expands at supersonic speeds. During this period, the excited atoms and ions transition from higher to lower energy states, emitting light radiation of specific wavelengths. High-sensitivity spectrometers are used to detect and analyze this light radiation, providing information about the elemental composition of the sample.

The essence of LIBS spectra is plasma spectroscopy. Based on the basic theories of plasma diagnostics, we can use data from physical and chemical experiments on material luminescence to perform theoretical analyses, determining the plasma's electron and ion temperatures, number density, and particle composition.

Key aspects of LIBS spectroscopy include:

(1)Peak Wavelength: Line spectra serve as the fingerprint of particle species. If fingerprint radiation exists in the plasma, the presence of the species can be confirmed. To improve accuracy, multiple fingerprint lines are commonly used.

(2)Peak Intensity: According to Saha's equation, the intensity of the spectral line is a function of concentration. In Local Thermal Equilibrium (LTE) conditions, there's a linear relationship between atomic concentration and spectral line intensity.

(3)Spectral Line Broadening: The spectral line profile includes natural broadening, Doppler broadening, Stark broadening, pressure broadening, resonance broadening, van der Waals broadening, and instrumental broadening. Instrumental broadening is a significant factor in all broadening types, except in the case of ultra-high-resolution spectrometers.

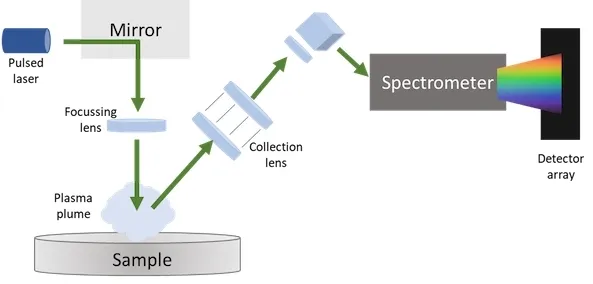

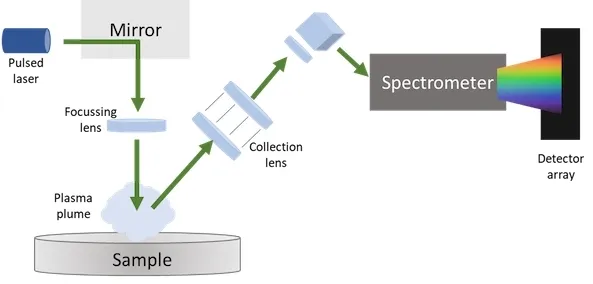

LIBS’Principle

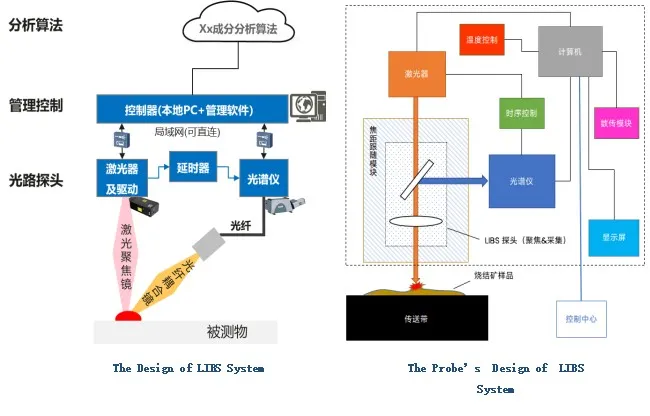

As illustrated, a LIBS analyzer typically consists of a laser, a laser focusing optical system, a spectra collection optical system, and a high-resolution spectrometer. Additionally, it often includes a specially designed timing control system, a sample chamber, and data analysis software.

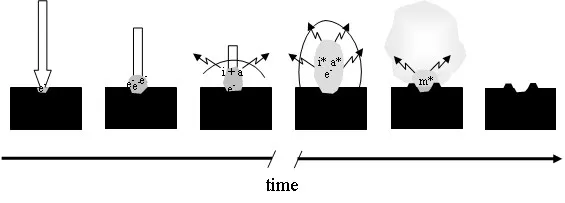

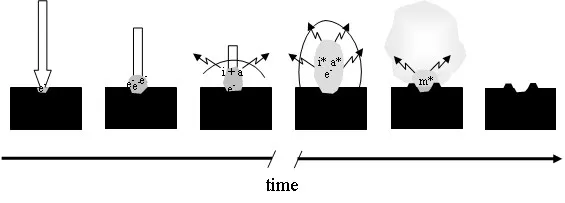

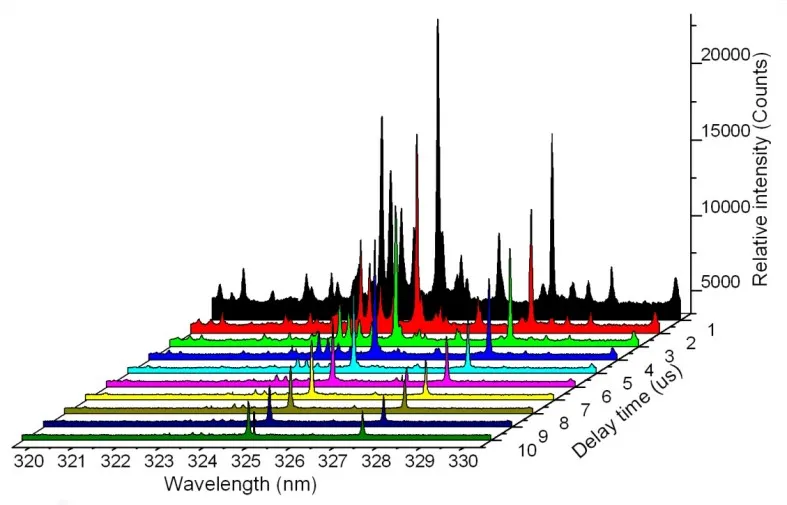

The dynamics of the Laser Induced Breakdown Spectroscopy (LIBS) process

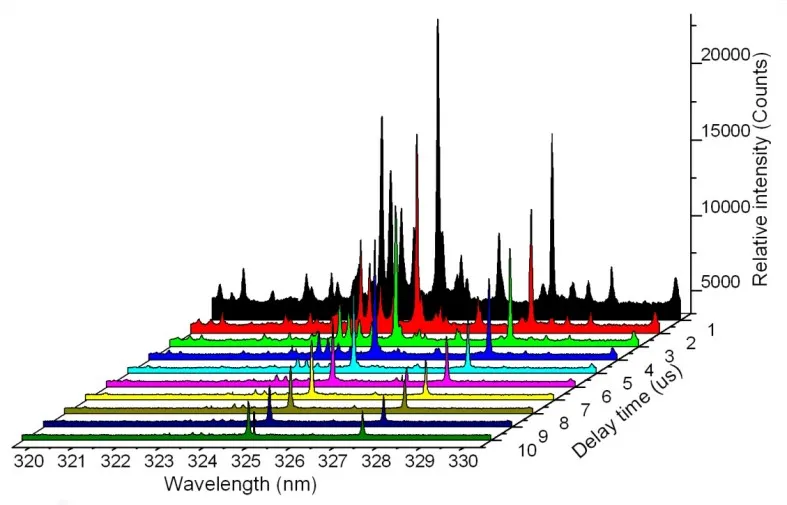

The LIBS spectrum is a complex process involving the excitation and interaction of negative electrons, free electrons, ions, atoms, and molecules. Using high time-resolution spectrometers to analyze LIBS signals reveals significant differences in the LIBS spectra collected at different times. This difference is due to the presence of bremsstrahlung radiation in the emission process of plasma spectra, primarily resulting from Coulomb interactions rather than electronic transitions creating characteristic spectral lines.

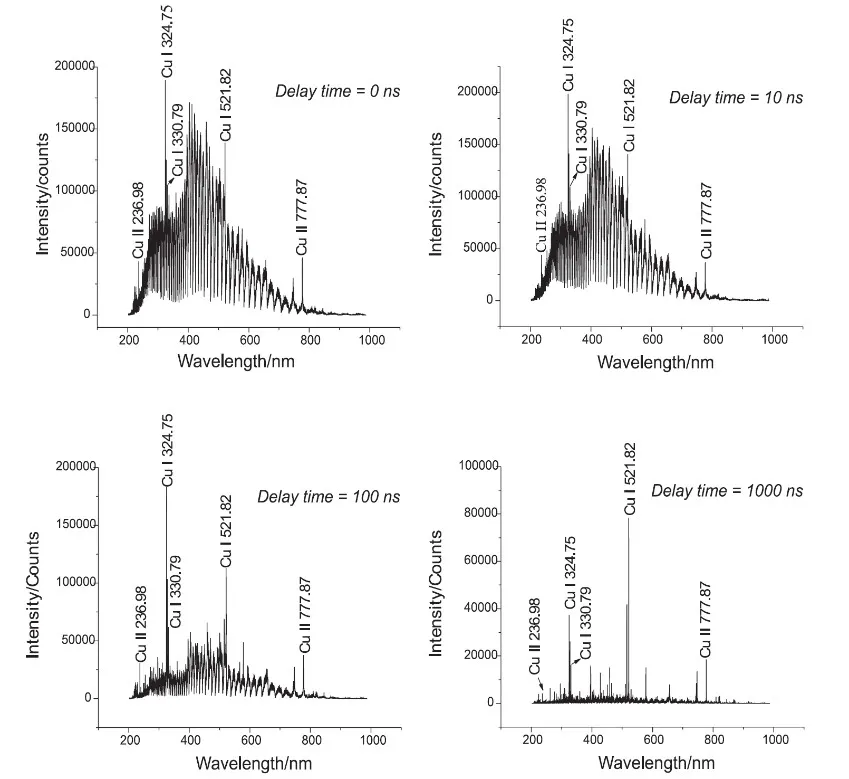

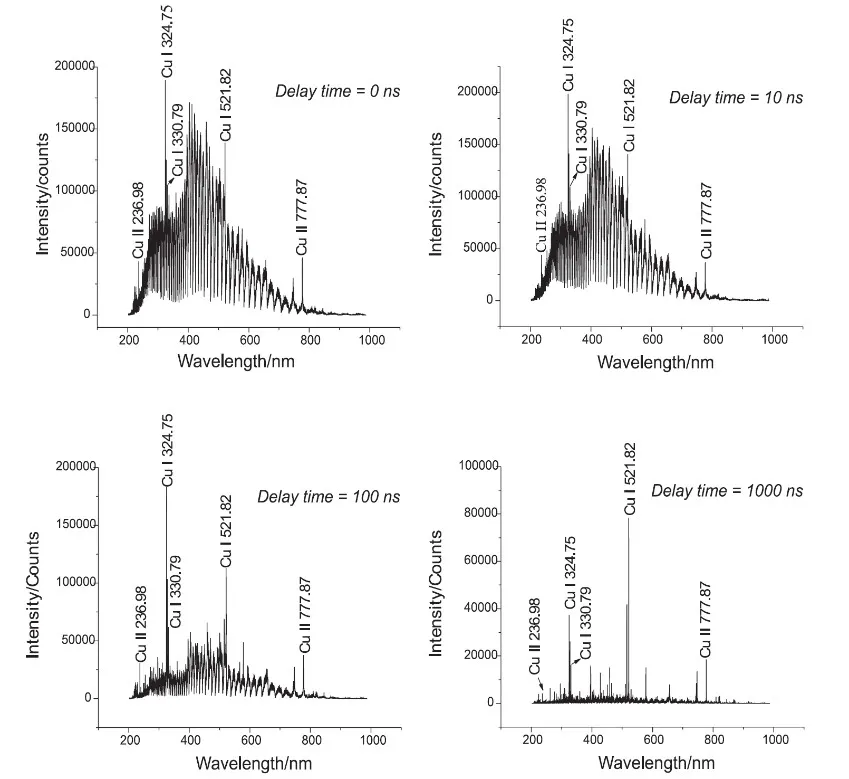

The LIBS Spectrum of Cu in different moment

For precise collection of optimal signal-to-noise ratio LIBS spectra, it is essential to control the spectrometer's timing to capture spectra at specific delay times, usually within an accuracy of 10µs or better.

The differences of LIBS Spectrum in different lag

The differences of LIBS Spectrum in different lag

Additionally, the exposure time of the spectrometer is a crucial factor: shorter exposure times prevent saturation during strong LIBS signals, while longer exposure times improve the signal-to-noise ratio during weaker signals.

To achieve stable plasma spectral signals from the laser hitting the material surface, it is necessary to precisely adjust the laser's energy and employ accurate and efficient focusing and collecting optical systems. This requires a stable-energy laser, precision optical systems, an accurate timing control system, a spectrometer with excellent timing precision and signal-to-noise ratio, and special data processing algorithms. These technical requirements are vital for qualitative and quantitative elemental.

iSpec-LIBS-IND

The principle

The principle of Laser Induced Breakdown Spectroscopy (LIBS) involves using high-intensity lasers to excite and eject a few micrograms of material from the surface of the sample. This process, often termed laser ablation, simultaneously produces a plasma with a very short lifespan but high brightness, reaching temperatures of up to 10,000℃. In this hot plasma, the ejected material dissociates into excited atoms and ions. After the laser pulse ends, the plasma cools rapidly as it expands at supersonic speeds. During this period, the excited atoms and ions transition from higher to lower energy states, emitting light radiation of specific wavelengths. High-sensitivity spectrometers are used to detect and analyze this light radiation, providing information about the elemental composition of the sample.

The essence of LIBS spectra is plasma spectroscopy. Based on the basic theories of plasma diagnostics, we can use data from physical and chemical experiments on material luminescence to perform theoretical analyses, determining the plasma's electron and ion temperatures, number density, and particle composition.

Key aspects of LIBS spectroscopy include:

(1)Peak Wavelength: Line spectra serve as the fingerprint of particle species. If fingerprint radiation exists in the plasma, the presence of the species can be confirmed. To improve accuracy, multiple fingerprint lines are commonly used.

(2)Peak Intensity: According to Saha's equation, the intensity of the spectral line is a function of concentration. In Local Thermal Equilibrium (LTE) conditions, there's a linear relationship between atomic concentration and spectral line intensity.

(3)Spectral Line Broadening: The spectral line profile includes natural broadening, Doppler broadening, Stark broadening, pressure broadening, resonance broadening, van der Waals broadening, and instrumental broadening. Instrumental broadening is a significant factor in all broadening types, except in the case of ultra-high-resolution spectrometers.

LIBS’Principle

As illustrated, a LIBS analyzer typically consists of a laser, a laser focusing optical system, a spectra collection optical system, and a high-resolution spectrometer. Additionally, it often includes a specially designed timing control system, a sample chamber, and data analysis software.

The dynamics of the Laser Induced Breakdown Spectroscopy (LIBS) process

The LIBS spectrum is a complex process involving the excitation and interaction of negative electrons, free electrons, ions, atoms, and molecules. Using high time-resolution spectrometers to analyze LIBS signals reveals significant differences in the LIBS spectra collected at different times. This difference is due to the presence of bremsstrahlung radiation in the emission process of plasma spectra, primarily resulting from Coulomb interactions rather than electronic transitions creating characteristic spectral lines.

The LIBS Spectrum of Cu in different moment

For precise collection of optimal signal-to-noise ratio LIBS spectra, it is essential to control the spectrometer's timing to capture spectra at specific delay times, usually within an accuracy of 10µs or better.

The differences of LIBS Spectrum in different lag

The differences of LIBS Spectrum in different lag

Additionally, the exposure time of the spectrometer is a crucial factor: shorter exposure times prevent saturation during strong LIBS signals, while longer exposure times improve the signal-to-noise ratio during weaker signals.

To achieve stable plasma spectral signals from the laser hitting the material surface, it is necessary to precisely adjust the laser's energy and employ accurate and efficient focusing and collecting optical systems. This requires a stable-energy laser, precision optical systems, an accurate timing control system, a spectrometer with excellent timing precision and signal-to-noise ratio, and special data processing algorithms. These technical requirements are vital for qualitative and quantitative elemental.

Applications

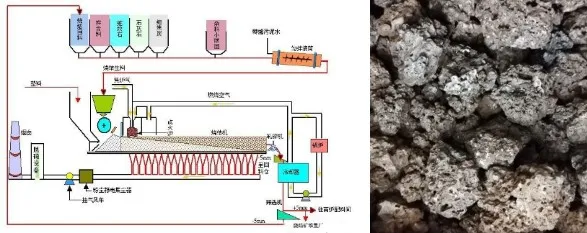

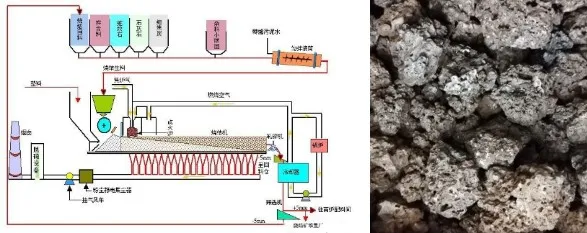

The LiSen Optics industrial online LIBS (Laser Induced Breakdown Spectroscopy) system is a pivotal component in the intelligent sensing system for sinter production by a renowned metallurgical engineering technology company in China. This system is applied in the sintering phase before blast furnace iron-making to perform real-time, online detection of the sinter's composition. It obtains critical parameters of the sinter, such as grade and alkalinity, to timely adjust the mix ratio and control production output.

Iron ore powder, due to its small particle size, poor air permeability, and tendency to cause blast furnace collapse, is typically formed into sinter before being used in blast furnace iron-making. Sinter, characterized by larger particle size, a porous structure, and greater strength, ensures the smooth operation of the blast furnace. Sintering involves a process where various powdered iron materials, along with appropriate amounts of fuel and flux, are mixed, balled, and then undergo a series of physical and chemical changes in the sintering equipment, causing the powder particles to bond into lumps.

Two important parameters of sinter are grade and alkalinity. Grade refers to the iron (Fe) content, while alkalinity is the ratio of calcium oxide (CaO) to silicon dioxide (SiO2). A 1% change in grade can alter the blast furnace fuel ratio by 1%-1.5% and production by 2%-2.5%. If alkalinity drops below 1.85, each 0.1 decrease can lead to a 3.0%-3.5% increase in fuel ratio and a decrease in production. Conversely, excessively high alkalinity (>2.3) can also reduce output. By detecting elements like Fe, Si, and Ca, the grade and alkalinity (with optional Mg and Al elements) can be calculated.

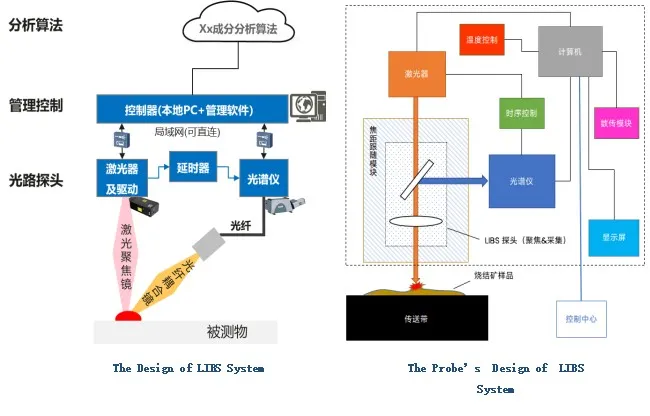

The LiSen Optics industrial online LIBS system is composed of three main parts: the optical probe (for online LIBS spectral collection), management control, and analysis algorithm. LiSen Optics is primarily responsible for the online LIBS spectral collection and management control. The system structure of the online LIBS spectral collection is outlined below.

Controlled by system software, the laser emits light which, via a specially designed LIBS probe and intelligent focal length following module, focuses on the sinter sample's surface to generate a LIBS signal. Simultaneously, the spectrometer, through specially designed timing control circuitry and software, achieves synchronous trigger collection, obtaining LIBS spectral information. The data is pre-processed and then analyzed using algorithms to calculate the quantities of Fe, CaO, and SiO2 for quantitative measurement.

Applications

The LiSen Optics industrial online LIBS (Laser Induced Breakdown Spectroscopy) system is a pivotal component in the intelligent sensing system for sinter production by a renowned metallurgical engineering technology company in China. This system is applied in the sintering phase before blast furnace iron-making to perform real-time, online detection of the sinter's composition. It obtains critical parameters of the sinter, such as grade and alkalinity, to timely adjust the mix ratio and control production output.

Iron ore powder, due to its small particle size, poor air permeability, and tendency to cause blast furnace collapse, is typically formed into sinter before being used in blast furnace iron-making. Sinter, characterized by larger particle size, a porous structure, and greater strength, ensures the smooth operation of the blast furnace. Sintering involves a process where various powdered iron materials, along with appropriate amounts of fuel and flux, are mixed, balled, and then undergo a series of physical and chemical changes in the sintering equipment, causing the powder particles to bond into lumps.

Two important parameters of sinter are grade and alkalinity. Grade refers to the iron (Fe) content, while alkalinity is the ratio of calcium oxide (CaO) to silicon dioxide (SiO2). A 1% change in grade can alter the blast furnace fuel ratio by 1%-1.5% and production by 2%-2.5%. If alkalinity drops below 1.85, each 0.1 decrease can lead to a 3.0%-3.5% increase in fuel ratio and a decrease in production. Conversely, excessively high alkalinity (>2.3) can also reduce output. By detecting elements like Fe, Si, and Ca, the grade and alkalinity (with optional Mg and Al elements) can be calculated.

The LiSen Optics industrial online LIBS system is composed of three main parts: the optical probe (for online LIBS spectral collection), management control, and analysis algorithm. LiSen Optics is primarily responsible for the online LIBS spectral collection and management control. The system structure of the online LIBS spectral collection is outlined below.

Controlled by system software, the laser emits light which, via a specially designed LIBS probe and intelligent focal length following module, focuses on the sinter sample's surface to generate a LIBS signal. Simultaneously, the spectrometer, through specially designed timing control circuitry and software, achieves synchronous trigger collection, obtaining LIBS spectral information. The data is pre-processed and then analyzed using algorithms to calculate the quantities of Fe, CaO, and SiO2 for quantitative measurement.

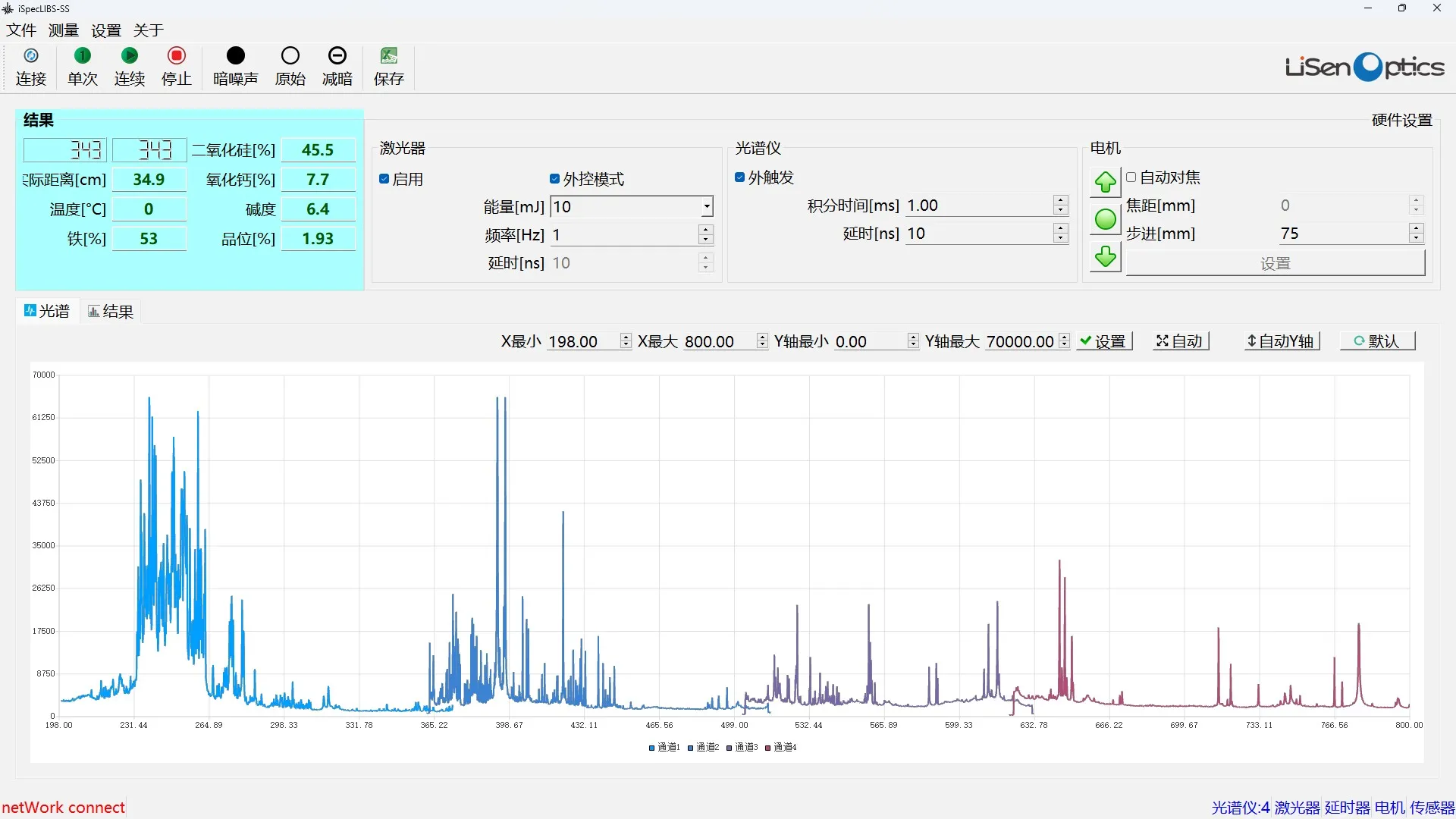

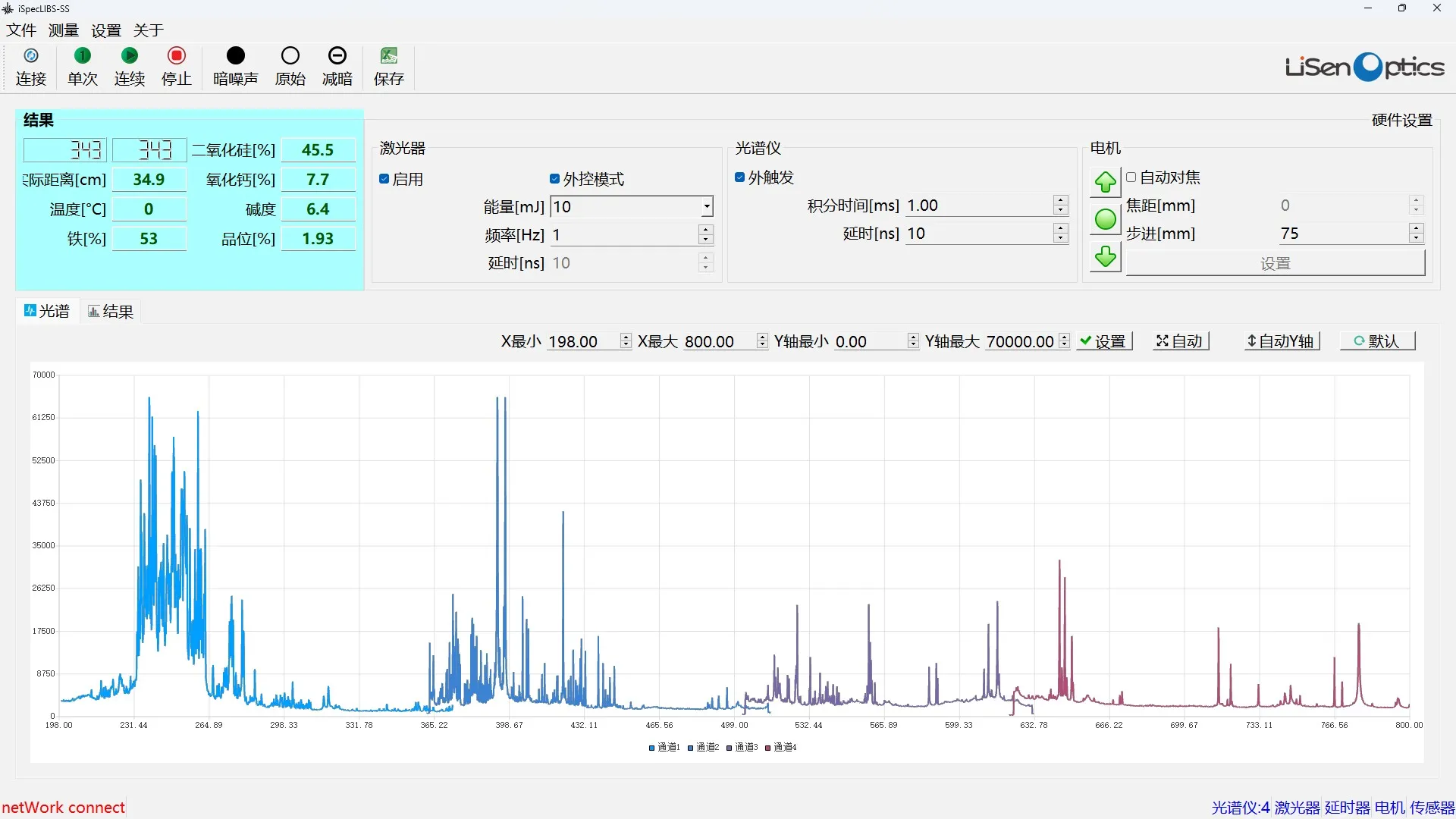

The software for the industrial online LIBS system's spectral data collection offers several functionalities:

(1) It can control various hardware modules to work in sync, allowing for the setting of parameters for the spectrometer (integration time, smoothing pixels, trigger delay, etc.), the laser (pulse energy, emission frequency, single/continuous mode, start/stop status, etc.), the delay timer (delay time), and focal length following (adjustment range, frequency, etc.).

(2) It enables real-time display of LIBS spectral curves, saving and exporting spectral data, and uploading final analysis results (contents of Fe, CaO, SiO2).

(3) The software can pre-process and filter spectral data for effectiveness (without processing, averaging, abnormal exclusion, etc., with configurable exclusion rules) before forwarding it to the analysis algorithm for calculation.

(4) It can receive computational results returned by the analysis algorithm, display them in real-time on the screen, and transmit them to the control center PLC mainframe via an internal protocol.

Software’s UI

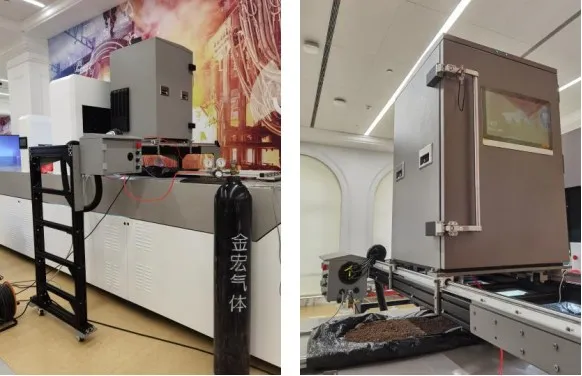

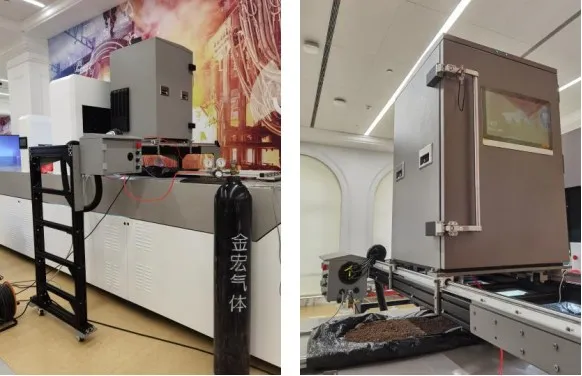

The Site where Installed Industrial Online LIBS System

Industrial Online LIBS System Filed Testing

The software for the industrial online LIBS system's spectral data collection offers several functionalities:

(1) It can control various hardware modules to work in sync, allowing for the setting of parameters for the spectrometer (integration time, smoothing pixels, trigger delay, etc.), the laser (pulse energy, emission frequency, single/continuous mode, start/stop status, etc.), the delay timer (delay time), and focal length following (adjustment range, frequency, etc.).

(2) It enables real-time display of LIBS spectral curves, saving and exporting spectral data, and uploading final analysis results (contents of Fe, CaO, SiO2).

(3) The software can pre-process and filter spectral data for effectiveness (without processing, averaging, abnormal exclusion, etc., with configurable exclusion rules) before forwarding it to the analysis algorithm for calculation.

(4) It can receive computational results returned by the analysis algorithm, display them in real-time on the screen, and transmit them to the control center PLC mainframe via an internal protocol.

Software’s UI

The Site where Installed Industrial Online LIBS System

Industrial Online LIBS System Filed Testing

Prev: Remote LIBS System

Next: no data!

Send Inquiry