Focus on spectral sensing and optoelectronic application systems

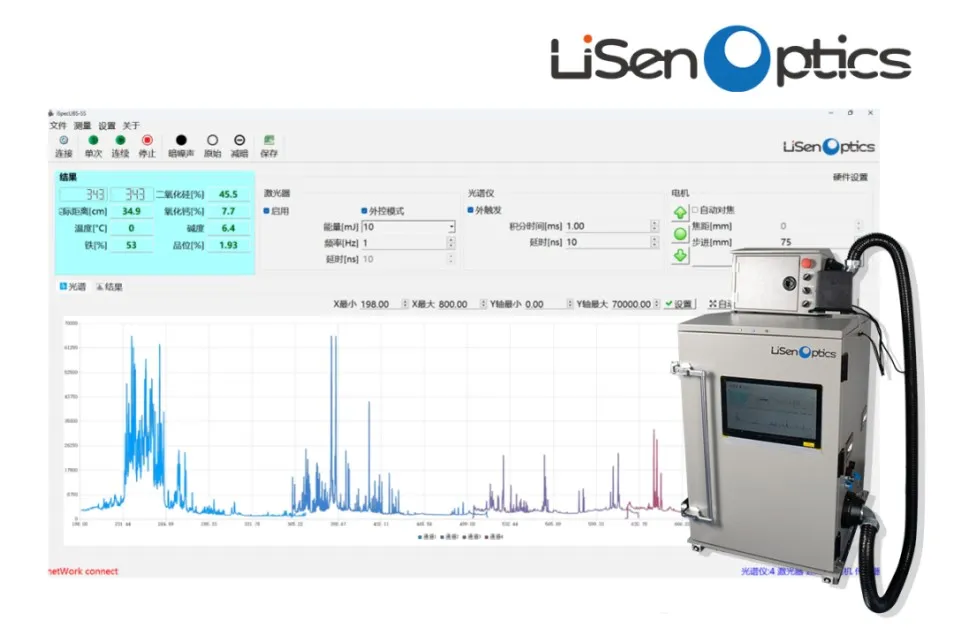

LIBS (Laser-Induced Breakdown Spectroscopy) System)

Time:2025-01-14

Abstract:In the study of ancient ceramics, the measurement and analysis of the chemical composition of both the surface and the interior elements are of great importance. These results can provide insights into the origin of the ceramics, the types of raw materials used, the evolution of the firing techniques, and the production sites.

Laser-Induced Breakdown Spectroscopy (LIBS) Analysis of Surface and Depth Distribution of Metal and Ceramic Artifacts' Composition

Due to the influence of external environmental factors and inherent structural defects, bronze artifacts exhibit varying degrees of corrosion. The rust morphology and associated products on the surface of bronze artifacts can partially reflect the principles and processes of corrosion. To effectively restore and preserve bronze artifacts, it is essential to explore the corrosion mechanisms on both their surface and interior. This understanding facilitates the adoption of correct and effective protective measures.

In the study of ancient ceramics, it is crucial to measure and analyze the chemical composition of both surface and internal elements. These results can provide insights into the origin of the ceramics, the types of raw materials used, the evolution of firing techniques, and the production locations.

01 Experimental Content

Compared to other spectroscopic analysis techniques, such as X-ray fluorescence spectrometry (XRF), inductively coupled plasma optical emission spectrometry (ICP-OES), and inductively coupled plasma mass spectrometry (ICP-MS), LIBS equipment offers three main advantages:

1、Open Sample Chamber: The LIBS equipment features an open sample chamber, allowing larger samples to be directly placed for in-situ analysis. It imposes no requirements on the sample's shape, properties, or flatness, eliminating the need for complex and time-consuming sample preparation processes.

2、Minimal Damage with Laser Pulses: Continuous laser pulses can be applied to the same point to obtain surface and depth elemental distribution information with minimal damage.

3、Detection of All Elements: LIBS can detect all elements in the periodic table, including lighter elements such as H, Li, and B.

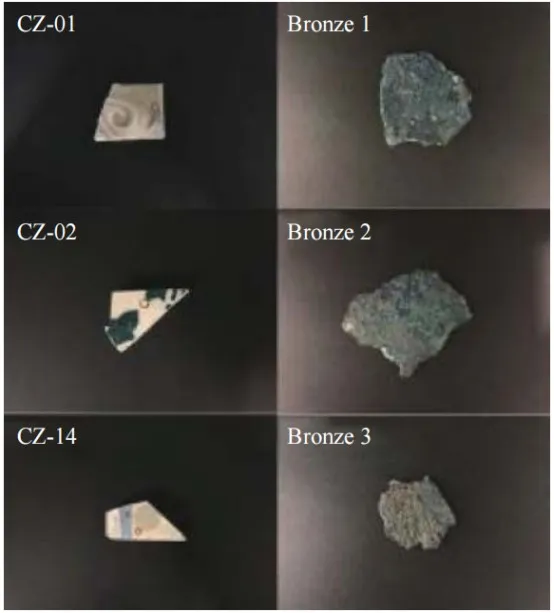

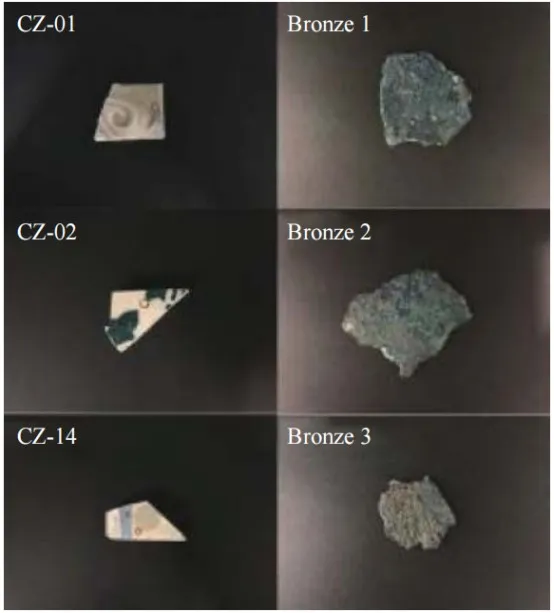

Figure 1: Physical Images of Bronze Artifacts and Ceramic Bricks

Figure 1: Physical Images of Bronze Artifacts and Ceramic Bricks

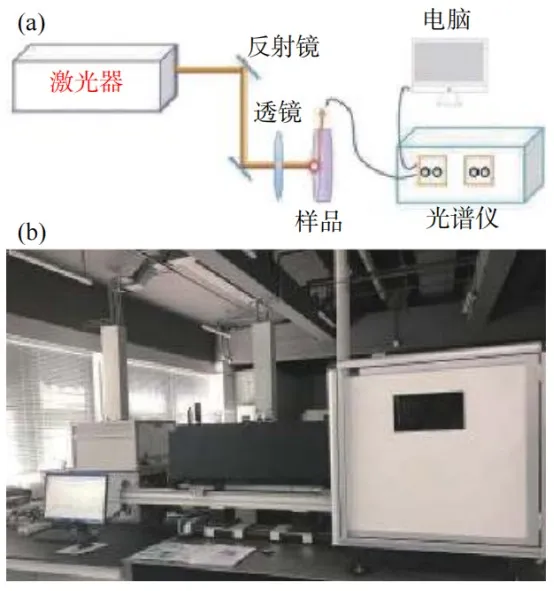

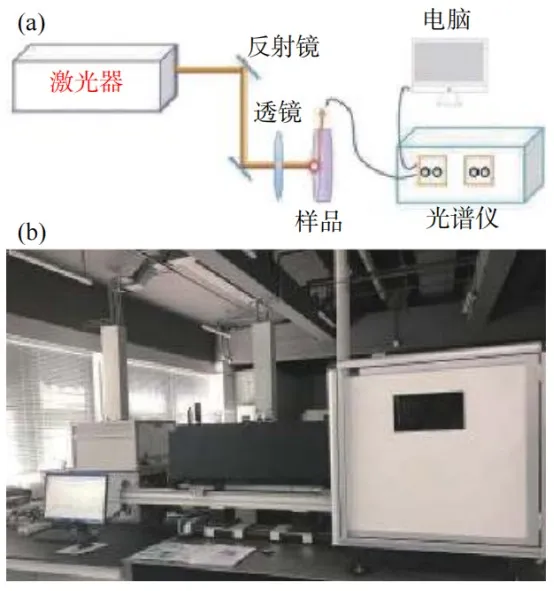

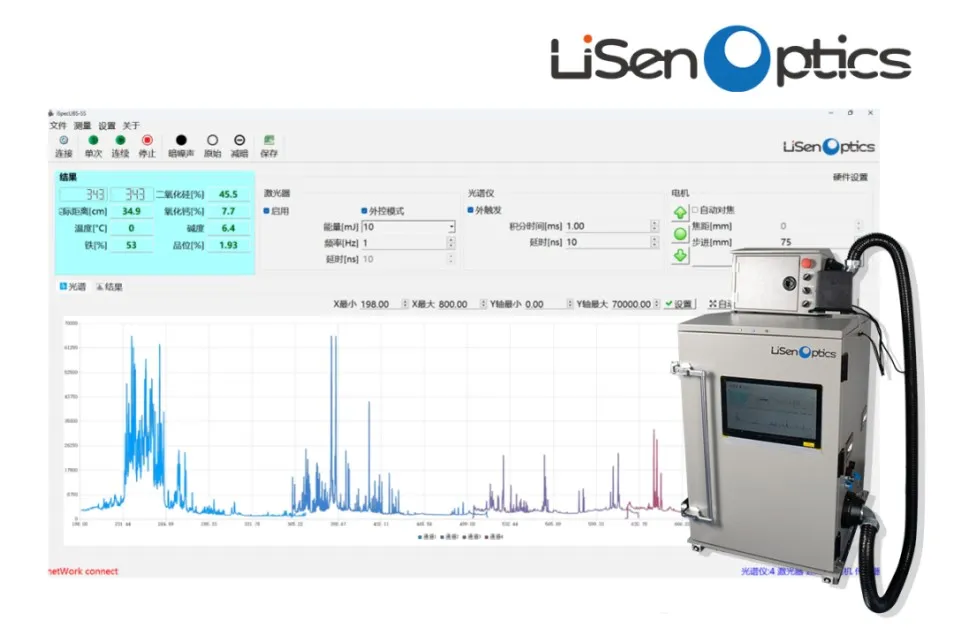

Figure 2: LIBS System Structure (a) Schematic Diagram and (b) Physical Image

Figure 2: LIBS System Structure (a) Schematic Diagram and (b) Physical Image

02 Experimental Results

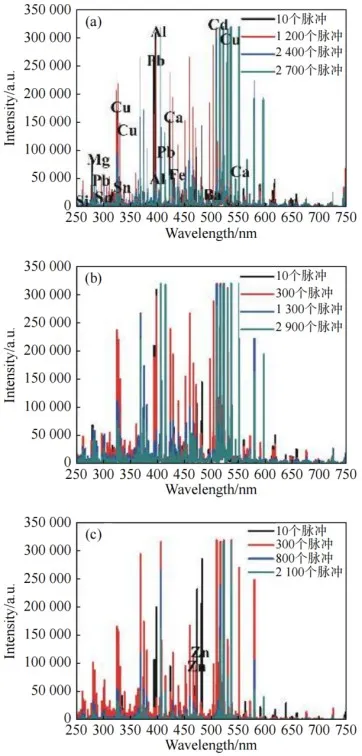

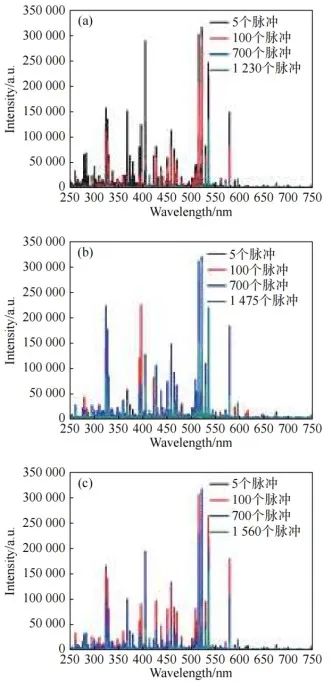

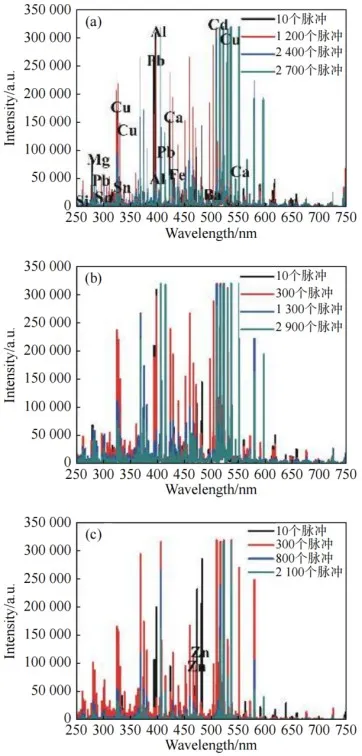

In the experiments on bronze artifacts, three points were selected on each bronze sample for LIBS spectral testing. Figure 3 (color version available in the journal's electronic edition) shows the surface and depth distribution spectra of elements for bronze1. In Figure 3(a), the laser single-pulse energy used was 26.2 mJ, and each spectral data point represents the accumulation of 10 laser pulses.

Figure 3: LIBS Spectra of Different Positions on Bronze1

The presence of elements such as Fe, Si, Na, Mg, and Al indicates that the sand and soil environment plays a role in the formation of the corrosion layer on the surface of the bronze artifacts. Under continuous pulse excitation, the Zn element can be observed on the bronze artifact. However, it only exists in the corrosion layer and not in the substrate itself. Further observation of the spectral results reveals that the surface of bronze2 contains abundant rare earth elements. The presence of these rare earth elements tends to form a protective oxide film, preventing further oxidation and corrosion. During the gradual ablation process of the laser, most of the rare earth elements disappear, suggesting that the elemental composition of the substrate is relatively simple, and the complexity of the surface composition arises from the elements in the corrosion layer.

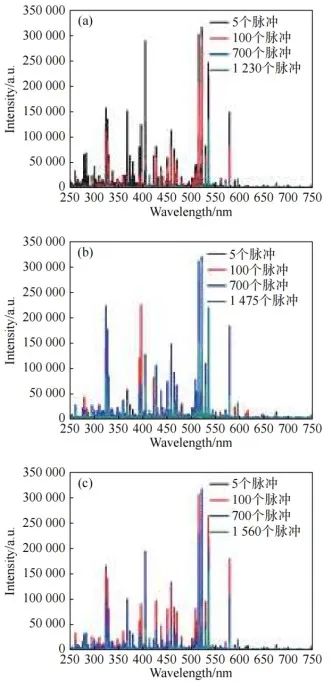

Figure 4: LIBS Spectra of Different Positions on Bronze2

Figure 4: LIBS Spectra of Different Positions on Bronze2

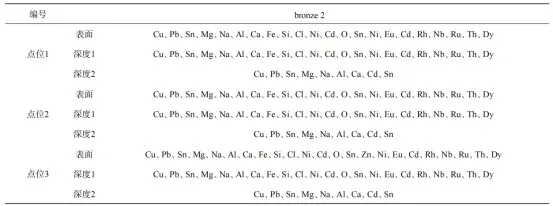

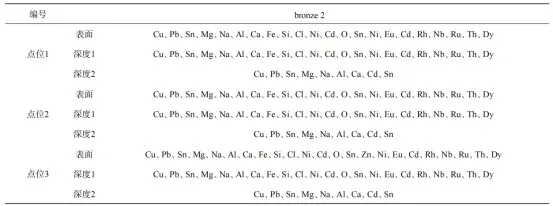

Table 1: Elemental Surface and Depth Distribution Results of Bronze2

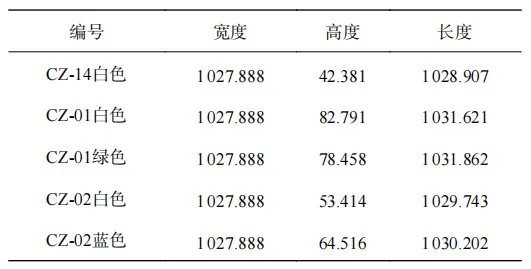

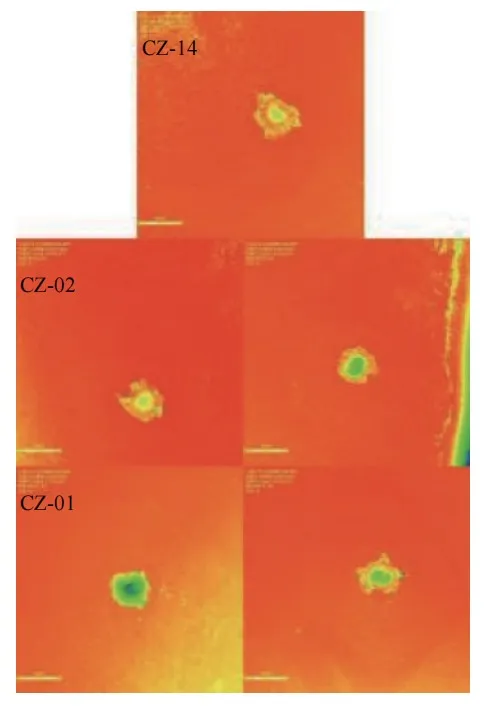

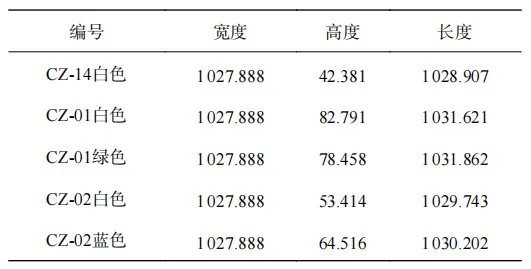

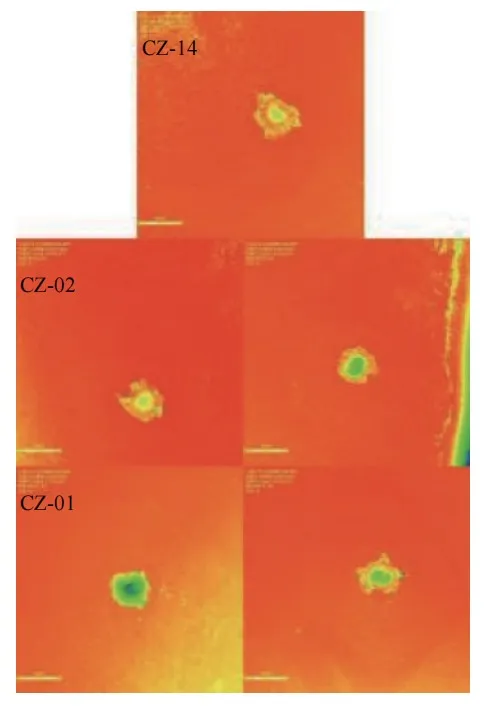

For the ceramic samples, since their surfaces are relatively flat, the average erosion depth of three ceramic tile samples was first tested using a confocal microscope. The average erosion depth per pulse for CZ-14 was 0.84 μm, for CZ-01, the average erosion depth of the white part was 1.66 μm, and the green part was 1.57 μm. For CZ-02, the average erosion depth of the white part was 1.07 μm, and the blue part was 1.29 μm. The morphology of the ceramic tile samples after being ablated by pulsed laser is shown in Figure 6 (color version available in the journal's electronic edition).

Table 2: Average Erosion Depth of Ceramic Tile Samples at Different Positions

Figure 5: Confocal Microscopy Erosion Depth Morphology of Ceramic Tile Samples

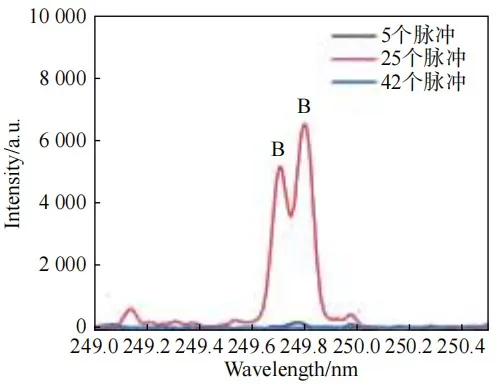

Figure 6: Spectra of B Element Variation with Number of Pulses

Figure 6: Spectra of B Element Variation with Number of Pulses

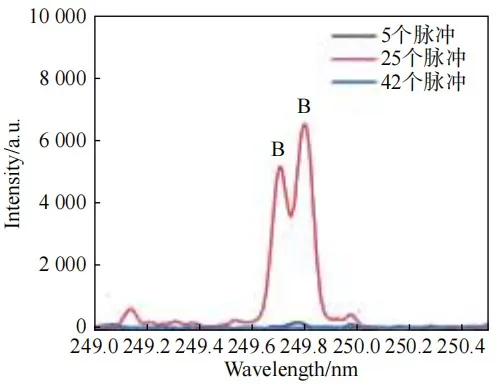

When the number of laser pulses for the white part is 40 or 41, the change in elemental composition indicates that the laser has reached the interface between two different layers. The estimated thickness of this layer is approximately 67 μm. As the number of laser pulses continues to increase, the elemental composition remains unchanged. However, when the pulse count reaches around 2000, the signal-to-noise ratio of the system deteriorates, making it difficult to distinguish elements. For the green part, when the number of laser pulses is 25 or 26, the variation in B element suggests that the laser has reached the interface between two different layers. The trend of this change is shown in Figure 9 (color version available in the journal's electronic edition). From this, the estimated thickness of the layer is approximately 40 μm.

03 Experimental Conclusion

Laser-Induced Breakdown Spectroscopy (LIBS) was used to study the surface and depth distribution of the components in bronze artifacts unearthed from the Guozhuang Chu Tombs in Shangcai, Henan Province, and ceramic tiles from the Lingzhao Pavilion of the Forbidden City Museum. The advantages of LIBS technology lie in its minimal sample requirements, no need for sample pre-treatment, the ability to simultaneously measure multiple elements, and its speed and accuracy. Additionally, the laser provides a certain depth of ablation, enabling layer-by-layer analysis without the need for embedding the sample. Microscopic structural analysis revealed that both types of artifact samples exhibit a layered structure. The elemental surface and depth distribution analysis helps to understand the corrosion mechanisms of the bronze artifacts' surface corrosion layers, thus providing scientific methods for their protection.

Recommendation:

Application of Laser-Induced Breakdown Spectroscopy (LIBS) in the Low-Carbon Steel Metallurgy Industry

The LIBS system utilizes ultra-short laser pulses to focus on the sample surface, forming plasma. The plasma's emitted light is analyzed using a spectrometer, identifying the elemental composition of the sample. This technology enables material identification, classification, as well as qualitative and quantitative analysis, making it highly suitable for applications in the low-carbon steel metallurgy industry. LIBS offers real-time, precise detection and analysis of alloy compositions, helping to optimize production processes, improve material quality, and ensure compliance with environmental standards in steel manufacturing.

Abstract:In the study of ancient ceramics, the measurement and analysis of the chemical composition of both the surface and the interior elements are of great importance. These results can provide insights into the origin of the ceramics, the types of raw materials used, the evolution of the firing techniques, and the production sites.

Laser-Induced Breakdown Spectroscopy (LIBS) Analysis of Surface and Depth Distribution of Metal and Ceramic Artifacts' Composition

Due to the influence of external environmental factors and inherent structural defects, bronze artifacts exhibit varying degrees of corrosion. The rust morphology and associated products on the surface of bronze artifacts can partially reflect the principles and processes of corrosion. To effectively restore and preserve bronze artifacts, it is essential to explore the corrosion mechanisms on both their surface and interior. This understanding facilitates the adoption of correct and effective protective measures.

In the study of ancient ceramics, it is crucial to measure and analyze the chemical composition of both surface and internal elements. These results can provide insights into the origin of the ceramics, the types of raw materials used, the evolution of firing techniques, and the production locations.

01 Experimental Content

Compared to other spectroscopic analysis techniques, such as X-ray fluorescence spectrometry (XRF), inductively coupled plasma optical emission spectrometry (ICP-OES), and inductively coupled plasma mass spectrometry (ICP-MS), LIBS equipment offers three main advantages:

1、Open Sample Chamber: The LIBS equipment features an open sample chamber, allowing larger samples to be directly placed for in-situ analysis. It imposes no requirements on the sample's shape, properties, or flatness, eliminating the need for complex and time-consuming sample preparation processes.

2、Minimal Damage with Laser Pulses: Continuous laser pulses can be applied to the same point to obtain surface and depth elemental distribution information with minimal damage.

3、Detection of All Elements: LIBS can detect all elements in the periodic table, including lighter elements such as H, Li, and B.

Figure 1: Physical Images of Bronze Artifacts and Ceramic Bricks

Figure 1: Physical Images of Bronze Artifacts and Ceramic Bricks

Figure 2: LIBS System Structure (a) Schematic Diagram and (b) Physical Image

Figure 2: LIBS System Structure (a) Schematic Diagram and (b) Physical Image

02 Experimental Results

In the experiments on bronze artifacts, three points were selected on each bronze sample for LIBS spectral testing. Figure 3 (color version available in the journal's electronic edition) shows the surface and depth distribution spectra of elements for bronze1. In Figure 3(a), the laser single-pulse energy used was 26.2 mJ, and each spectral data point represents the accumulation of 10 laser pulses.

Figure 3: LIBS Spectra of Different Positions on Bronze1

The presence of elements such as Fe, Si, Na, Mg, and Al indicates that the sand and soil environment plays a role in the formation of the corrosion layer on the surface of the bronze artifacts. Under continuous pulse excitation, the Zn element can be observed on the bronze artifact. However, it only exists in the corrosion layer and not in the substrate itself. Further observation of the spectral results reveals that the surface of bronze2 contains abundant rare earth elements. The presence of these rare earth elements tends to form a protective oxide film, preventing further oxidation and corrosion. During the gradual ablation process of the laser, most of the rare earth elements disappear, suggesting that the elemental composition of the substrate is relatively simple, and the complexity of the surface composition arises from the elements in the corrosion layer.

Figure 4: LIBS Spectra of Different Positions on Bronze2

Figure 4: LIBS Spectra of Different Positions on Bronze2

Table 1: Elemental Surface and Depth Distribution Results of Bronze2

For the ceramic samples, since their surfaces are relatively flat, the average erosion depth of three ceramic tile samples was first tested using a confocal microscope. The average erosion depth per pulse for CZ-14 was 0.84 μm, for CZ-01, the average erosion depth of the white part was 1.66 μm, and the green part was 1.57 μm. For CZ-02, the average erosion depth of the white part was 1.07 μm, and the blue part was 1.29 μm. The morphology of the ceramic tile samples after being ablated by pulsed laser is shown in Figure 6 (color version available in the journal's electronic edition).

Table 2: Average Erosion Depth of Ceramic Tile Samples at Different Positions

Figure 5: Confocal Microscopy Erosion Depth Morphology of Ceramic Tile Samples

Figure 6: Spectra of B Element Variation with Number of Pulses

Figure 6: Spectra of B Element Variation with Number of Pulses

When the number of laser pulses for the white part is 40 or 41, the change in elemental composition indicates that the laser has reached the interface between two different layers. The estimated thickness of this layer is approximately 67 μm. As the number of laser pulses continues to increase, the elemental composition remains unchanged. However, when the pulse count reaches around 2000, the signal-to-noise ratio of the system deteriorates, making it difficult to distinguish elements. For the green part, when the number of laser pulses is 25 or 26, the variation in B element suggests that the laser has reached the interface between two different layers. The trend of this change is shown in Figure 9 (color version available in the journal's electronic edition). From this, the estimated thickness of the layer is approximately 40 μm.

03 Experimental Conclusion

Laser-Induced Breakdown Spectroscopy (LIBS) was used to study the surface and depth distribution of the components in bronze artifacts unearthed from the Guozhuang Chu Tombs in Shangcai, Henan Province, and ceramic tiles from the Lingzhao Pavilion of the Forbidden City Museum. The advantages of LIBS technology lie in its minimal sample requirements, no need for sample pre-treatment, the ability to simultaneously measure multiple elements, and its speed and accuracy. Additionally, the laser provides a certain depth of ablation, enabling layer-by-layer analysis without the need for embedding the sample. Microscopic structural analysis revealed that both types of artifact samples exhibit a layered structure. The elemental surface and depth distribution analysis helps to understand the corrosion mechanisms of the bronze artifacts' surface corrosion layers, thus providing scientific methods for their protection.

Recommendation:

Application of Laser-Induced Breakdown Spectroscopy (LIBS) in the Low-Carbon Steel Metallurgy Industry

The LIBS system utilizes ultra-short laser pulses to focus on the sample surface, forming plasma. The plasma's emitted light is analyzed using a spectrometer, identifying the elemental composition of the sample. This technology enables material identification, classification, as well as qualitative and quantitative analysis, making it highly suitable for applications in the low-carbon steel metallurgy industry. LIBS offers real-time, precise detection and analysis of alloy compositions, helping to optimize production processes, improve material quality, and ensure compliance with environmental standards in steel manufacturing.

Previous: No data