Focus on spectral sensing and optoelectronic application systems

Handheld LIBS System

The handheld LIBS laser-induced breakdown spectroscopy system utilizes laser-induced breakdown spectroscopy, specifically designed for carbon analysis in metals and alloys. It features rapid detection, good performance, compact size, and easy portability. It can be taken to locations where large instruments are inconvenient, offering a broader application range. Operators can perform Positive Material Identification (PMI) to analyze pipeline materials facing flow-accelerated corrosion or sulfidation corrosion. Within seconds, one can verify the composition of pipelines, valves, and reactors. Its conical front end helps expand its coverage, allowing measurement of hard-to-reach areas.

The handheld LIBS laser-induced breakdown spectroscopy system utilizes laser-induced breakdown spectroscopy, specifically designed for carbon analysis in metals and alloys. It features rapid detection, good performance, compact size, and easy portability. It can be taken to locations where large instruments are inconvenient, offering a broader application range. Operators can perform Positive Material Identification (PMI) to analyze pipeline materials facing flow-accelerated corrosion or sulfidation corrosion. Within seconds, one can verify the composition of pipelines, valves, and reactors. Its conical front end helps expand its coverage, allowing measurement of hard-to-reach areas.

Product Introduction

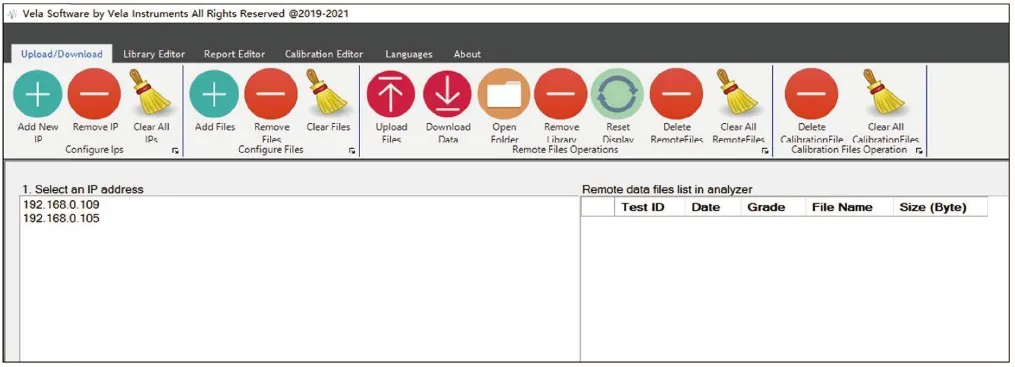

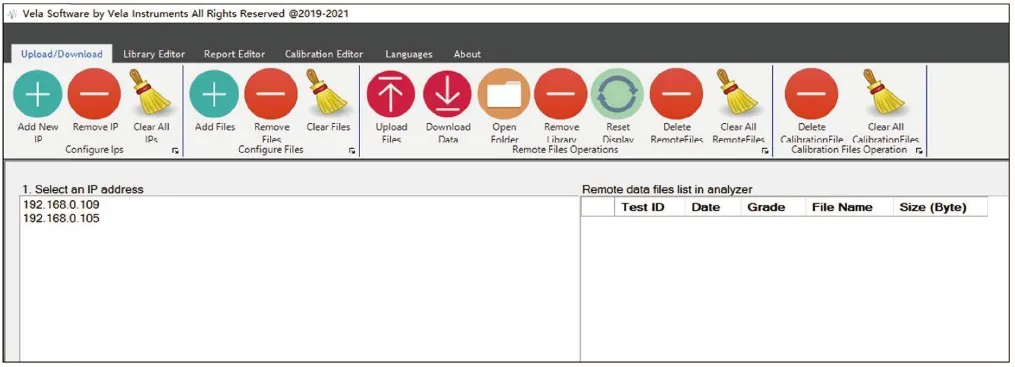

The handheld LIBS laser-induced breakdown spectroscopy system comes with complimentary client software, providing robust tools to download test data, edit grade libraries, generate test reports, and compile calibration files. It can test a variety of elements, and the database includes over 100 of the most commonly used alloy grades. The software allows for advanced customization, projecting the screen display to PCs or mobile devices, and remotely triggering tests.

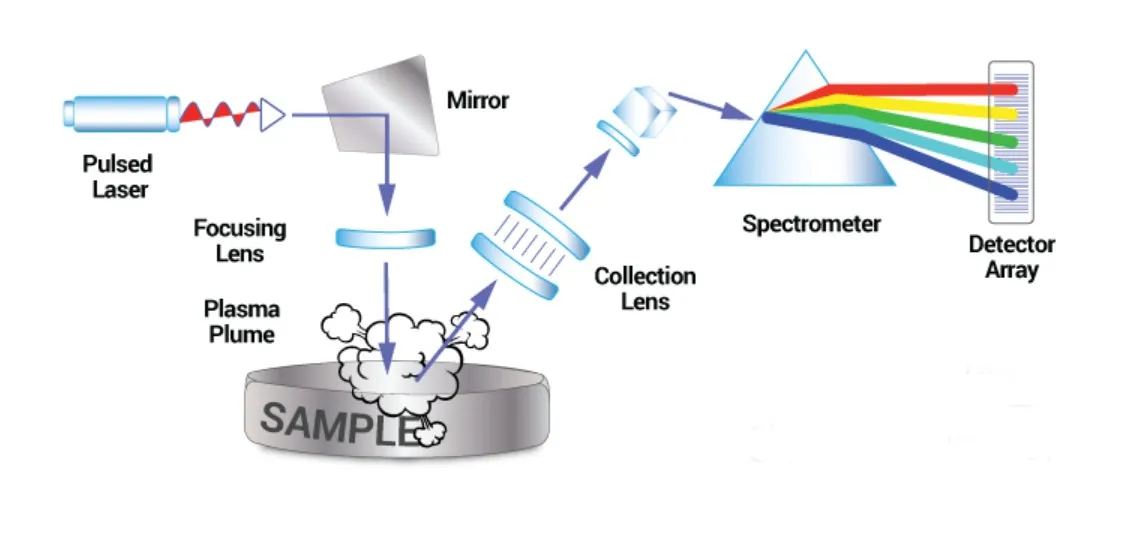

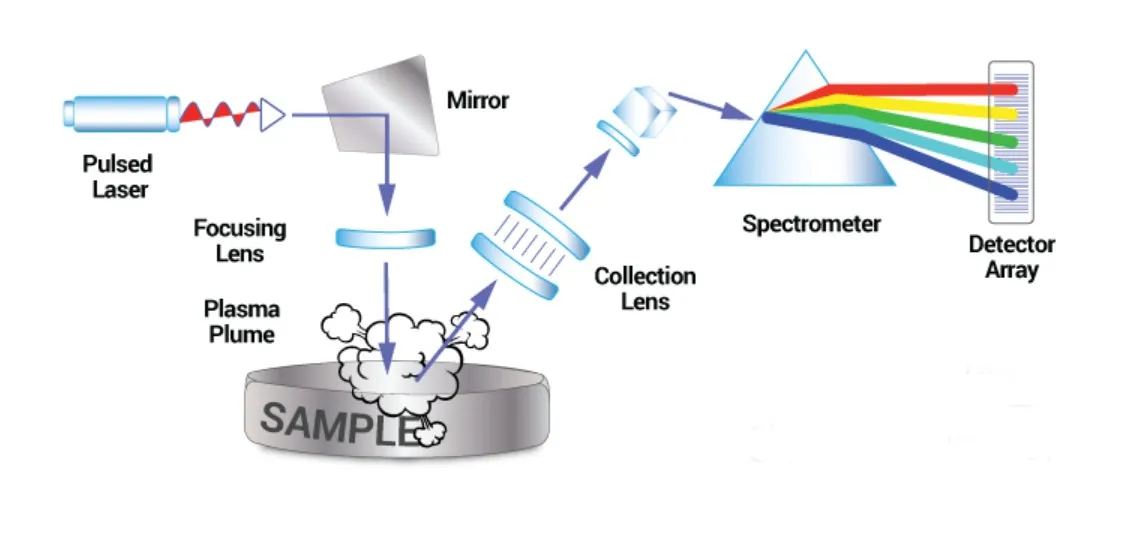

LIBS Principle

Product Detail

● High-Capacity Lithium-Ion Battery & DC Power Adapter

Equipped with a universal DC power adapter for uninterrupted power supply.

Includes three high-capacity lithium-ion batteries, each providing up to 3 hours of operational time, ensuring continuous operation all day.

● Large Touch Screen

Features a touch screen that is resistant to electromagnetic interference, making it suitable for industrial applications.

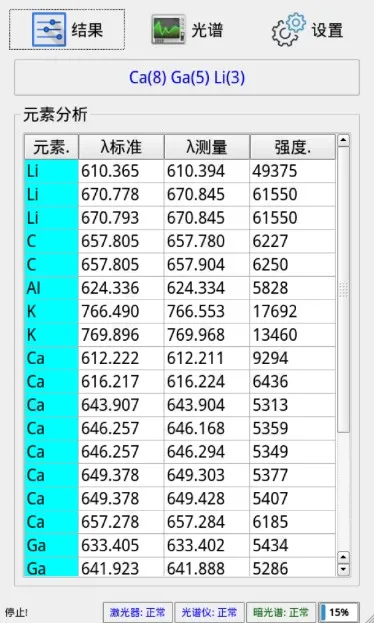

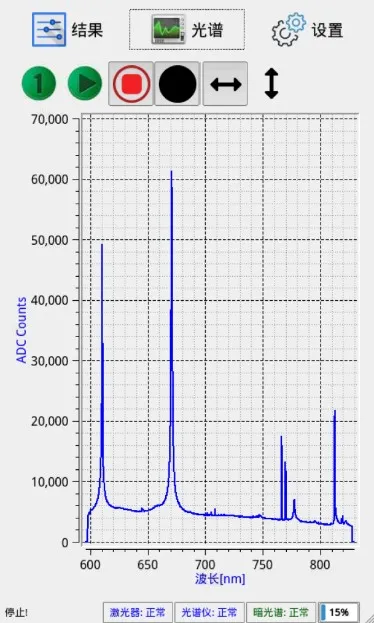

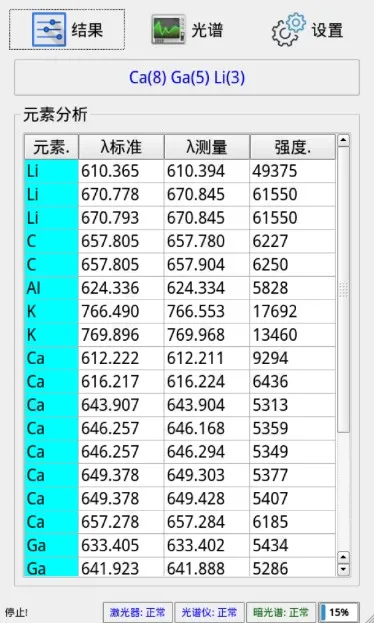

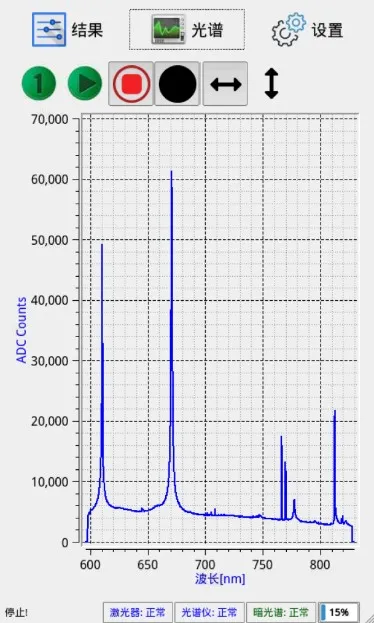

The Spectrum of Li

|

|

● Lightweight Handheld Probe

Weighing approximately 1.25Kg, the system is compact and ergonomically designed for comfortable and efficient long-term use.

|

|

The handheld LIBS laser-induced breakdown spectroscopy system comes with complimentary client software, providing robust tools to download test data, edit grade libraries, generate test reports, and compile calibration files. It can test a variety of elements, and the database includes over 100 of the most commonly used alloy grades. The software allows for advanced customization, projecting the screen display to PCs or mobile devices, and remotely triggering tests.

LIBS Principle

Product Detail

● High-Capacity Lithium-Ion Battery & DC Power Adapter

Equipped with a universal DC power adapter for uninterrupted power supply.

Includes three high-capacity lithium-ion batteries, each providing up to 3 hours of operational time, ensuring continuous operation all day.

● Large Touch Screen

Features a touch screen that is resistant to electromagnetic interference, making it suitable for industrial applications.

The Spectrum of Li

|

|

● Lightweight Handheld Probe

Weighing approximately 1.25Kg, the system is compact and ergonomically designed for comfortable and efficient long-term use.

|

|

Main Technical Features

● Based on Core LIBS Technology: No ionizing fluorescence radiation.

● High Precision Testing Mode: Utilizes algorithms to analyze and average multiple single test values.

● Element Testing: Capable of testing a wide range of elements. The database includes over 100 common alloy grades, with advanced customization available via software.

● Remote Display and Triggering: Screen display can be projected to PCs or smartphones, with remote testing trigger capability.

Main Technical Indicators

|

Model |

iSpec-LIBS-HH |

|

Laser |

Class 3B, 1064nm passive solid-state laser. |

|

Spectrometer |

Resolution <0.2nm; Spectral Range |

|

Single Test Duration |

~1s. |

|

Alloy Matrix Compatibility |

Aluminum, magnesium, zinc, copper, low-alloy steel, alloy steel, stainless steel, titanium, cobalt, nickel-based alloys. |

|

Testable Elements |

Over 100 elements including Al, B, Be, Bi, Co, Cr, Cu, Fe, Li, Mg, Mn, Mo, Nb, Ni, Pb, Si, Sn, Ti, V, Zn, Zr, etc. |

|

Sample Types |

Cylindrical, thin plates, wires with a diameter >1mm, foils (~0.02mm), large fragments (no powder). |

|

Display |

4.0-inch resistive touch screen, 320*480 pixels. |

|

Memory |

Standard 8GB, upgradable to 16GB. |

|

Waterproofing |

IP54 water and dust resistance. |

|

Safety |

Physical laser safety interlock device. |

|

Operating Temperature |

0-40℃ (recommended 5-35℃). |

|

Dimensions/Weight |

227mm x 86mm x 234mm, 2.45Kg. |

Typical Application

● Element Test

|

Element |

Min(%) |

Max(%) |

|

C |

0 |

1.5 |

|

Al |

0 |

1.5 |

|

Cr |

0 |

30 |

|

Cu |

0 |

4 |

|

Mn |

0 |

15 |

|

Mo |

0 |

5 |

|

Ni |

0 |

25 |

|

Si |

0 |

4 |

|

Ti |

0 |

1.5 |

|

Fe |

Balance |

Balance |

Element Testing Range Table

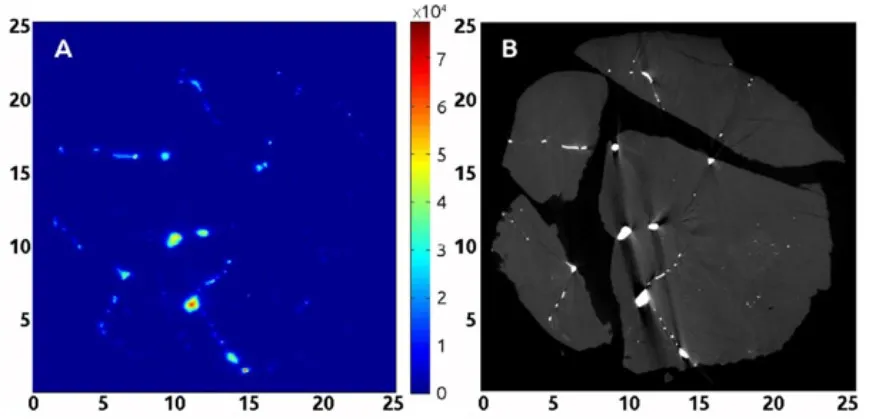

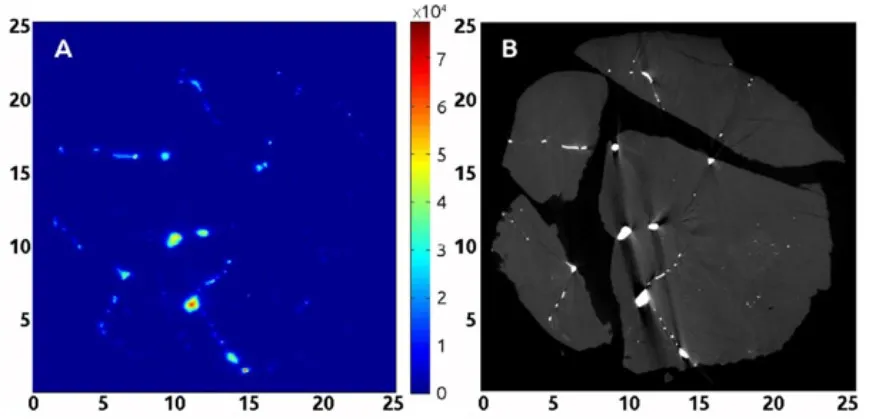

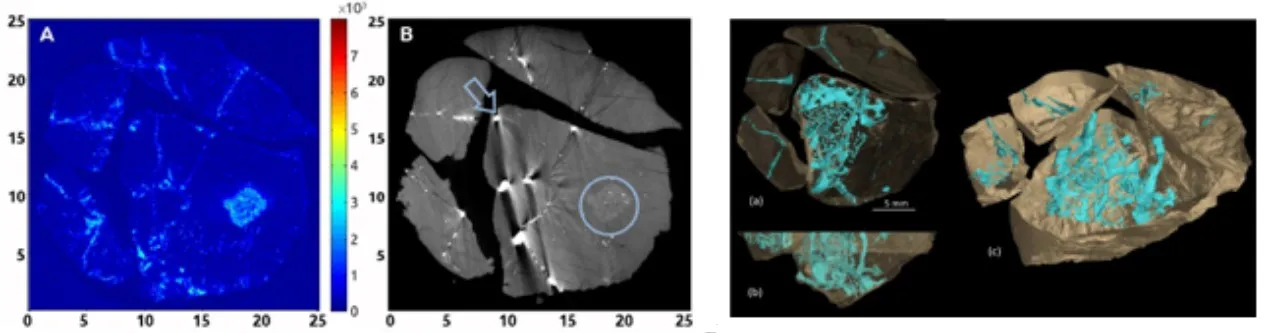

Pb Element (405.78nm) Planar Distribution Map Pb Element Measurement Plane Map

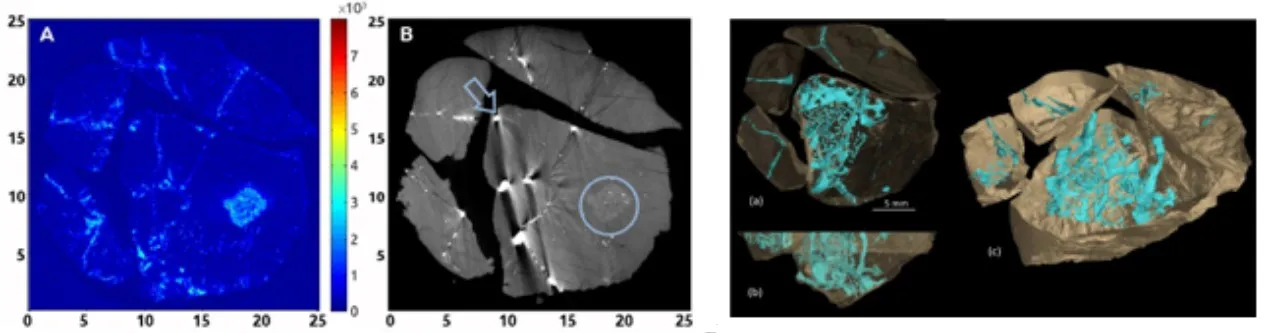

Ni Element (352.45nm) Planar Distribution Map Pb Element Measurement Plane Map Diagram Including Pb, Mineral 3D Distribution Map

Main Technical Features

● Based on Core LIBS Technology: No ionizing fluorescence radiation.

● High Precision Testing Mode: Utilizes algorithms to analyze and average multiple single test values.

● Element Testing: Capable of testing a wide range of elements. The database includes over 100 common alloy grades, with advanced customization available via software.

● Remote Display and Triggering: Screen display can be projected to PCs or smartphones, with remote testing trigger capability.

Main Technical Indicators

|

Model |

iSpec-LIBS-HH |

|

Laser |

Class 3B, 1064nm passive solid-state laser. |

|

Spectrometer |

Resolution <0.2nm; Spectral Range |

|

Single Test Duration |

~1s. |

|

Alloy Matrix Compatibility |

Aluminum, magnesium, zinc, copper, low-alloy steel, alloy steel, stainless steel, titanium, cobalt, nickel-based alloys. |

|

Testable Elements |

Over 100 elements including Al, B, Be, Bi, Co, Cr, Cu, Fe, Li, Mg, Mn, Mo, Nb, Ni, Pb, Si, Sn, Ti, V, Zn, Zr, etc. |

|

Sample Types |

Cylindrical, thin plates, wires with a diameter >1mm, foils (~0.02mm), large fragments (no powder). |

|

Display |

4.0-inch resistive touch screen, 320*480 pixels. |

|

Memory |

Standard 8GB, upgradable to 16GB. |

|

Waterproofing |

IP54 water and dust resistance. |

|

Safety |

Physical laser safety interlock device. |

|

Operating Temperature |

0-40℃ (recommended 5-35℃). |

|

Dimensions/Weight |

227mm x 86mm x 234mm, 2.45Kg. |

Typical Application

● Element Test

|

Element |

Min(%) |

Max(%) |

|

C |

0 |

1.5 |

|

Al |

0 |

1.5 |

|

Cr |

0 |

30 |

|

Cu |

0 |

4 |

|

Mn |

0 |

15 |

|

Mo |

0 |

5 |

|

Ni |

0 |

25 |

|

Si |

0 |

4 |

|

Ti |

0 |

1.5 |

|

Fe |

Balance |

Balance |

Element Testing Range Table

Pb Element (405.78nm) Planar Distribution Map Pb Element Measurement Plane Map

Ni Element (352.45nm) Planar Distribution Map Pb Element Measurement Plane Map Diagram Including Pb, Mineral 3D Distribution Map

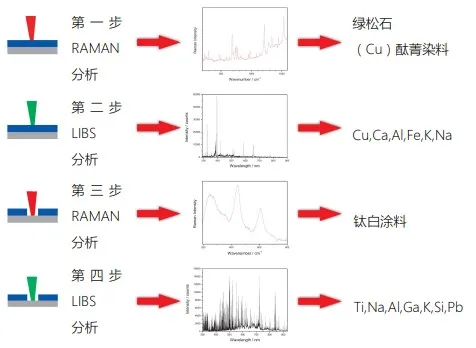

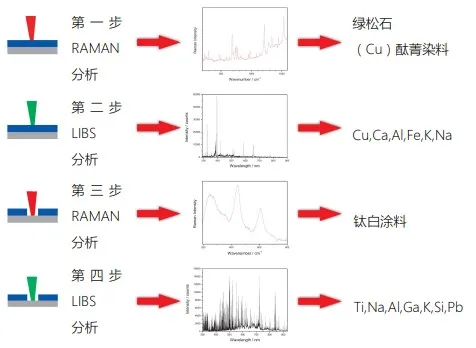

● Layered Sample Analysis

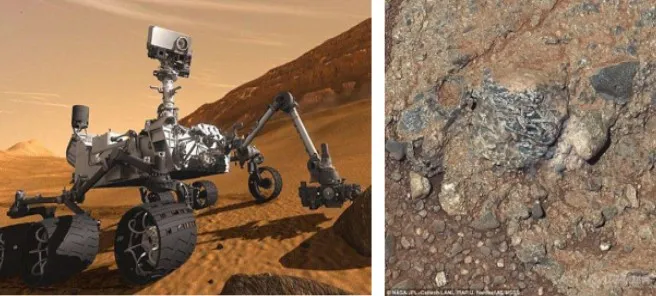

● Geological and Mineral Analysis

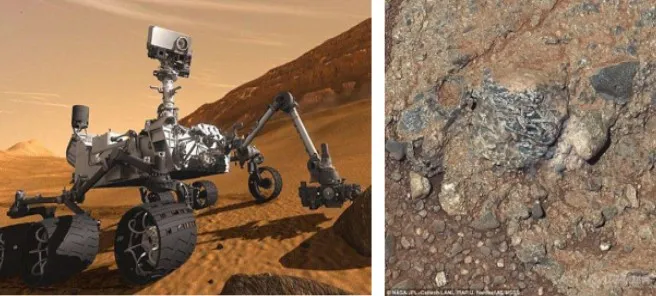

Used in NASA’s Mars rover Curiosity to analyze Martian rock and mineral composition.

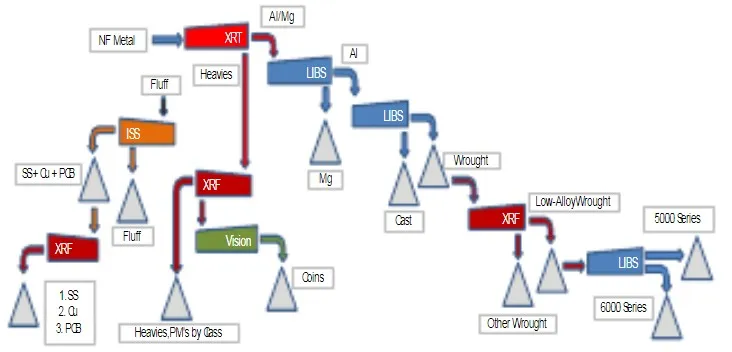

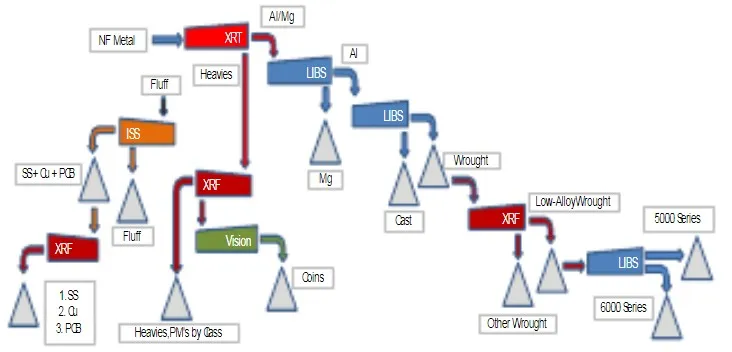

● Aluminum Material Testing

Effective tool for on-site aluminum alloy content testing in production.

Flow Chart of Dry Sorting Line for Aluminum Alloy Scrap

● Recycled Resources

Rapid grade identification for recycling aluminum resources.

● Quality Control

PMI quality control in industrial production, allowing on-site material analysis of components.

● Safe Laser Technology

Utilizes high-energy pulsed safety (Class 3B) laser technology without radiation hazards.

|

|

● Layered Sample Analysis

● Geological and Mineral Analysis

Used in NASA’s Mars rover Curiosity to analyze Martian rock and mineral composition.

● Aluminum Material Testing

Effective tool for on-site aluminum alloy content testing in production.

Flow Chart of Dry Sorting Line for Aluminum Alloy Scrap

● Recycled Resources

Rapid grade identification for recycling aluminum resources.

● Quality Control

PMI quality control in industrial production, allowing on-site material analysis of components.

● Safe Laser Technology

Utilizes high-energy pulsed safety (Class 3B) laser technology without radiation hazards.

|

|

Prev: Modular LIBS System

Next: Portable LIBS System

Send Inquiry