Focus on spectral sensing and optoelectronic application systems

Integrated LIBS System

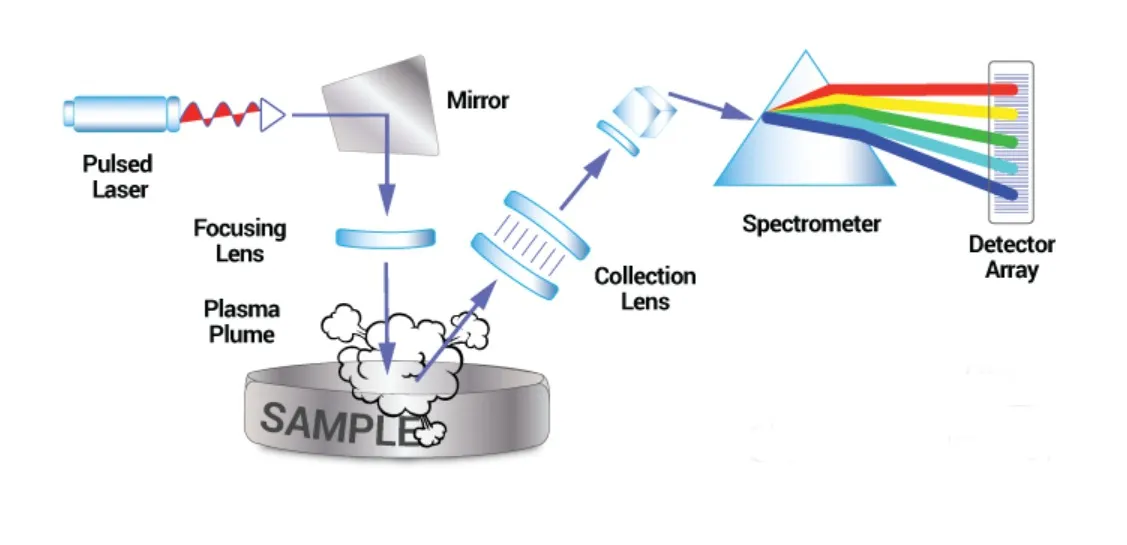

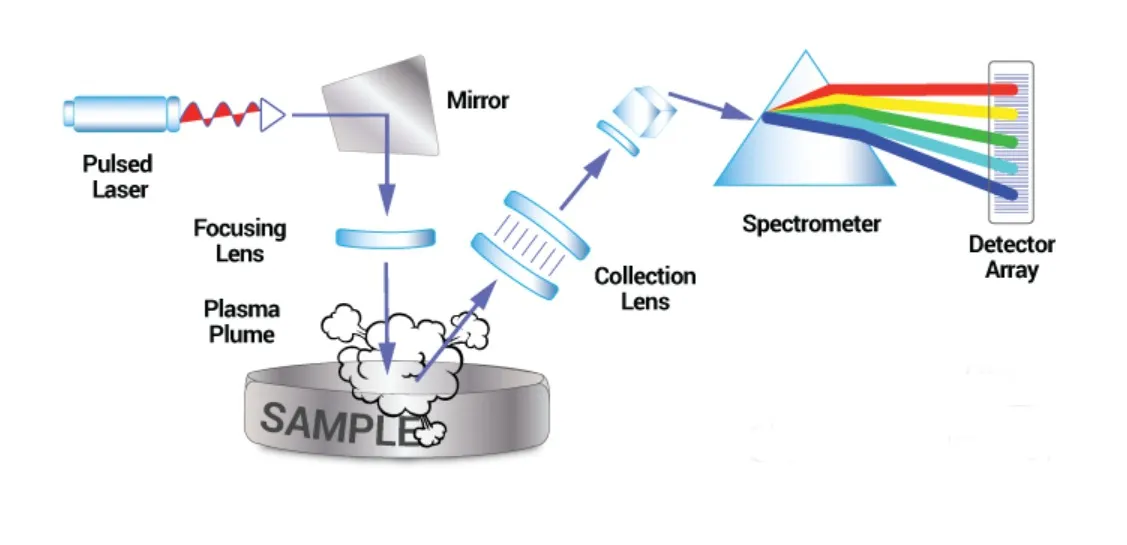

LIBS (Laser Induced Breakdown Spectroscopy) is a sophisticated analytical technique that involves the use of ultra-short pulse lasers to focus on the surface of a sample, creating plasma. This plasma, a highly energized form of matter, emits light that is characteristic of the elements present in the sample. By analyzing this emitted light spectrum with a spectrometer, LIBS systems can identify the elemental composition of the sample. This process allows for the identification, classification, qualitative, and quantitative analysis of materials.

LIBS (Laser Induced Breakdown Spectroscopy) is a sophisticated analytical technique that involves the use of ultra-short pulse lasers to focus on the surface of a sample, creating plasma. This plasma, a highly energized form of matter, emits light that is characteristic of the elements present in the sample. By analyzing this emitted light spectrum with a spectrometer, LIBS systems can identify the elemental composition of the sample. This process allows for the identification, classification, qualitative, and quantitative analysis of materials.

Product Introduction

The iSpec-LIBS800 system is a comprehensive, integrated solution for performing Laser Induced Breakdown Spectroscopy, a technique used for elemental analysis of materials. This technique involves focusing ultra-short pulse lasers onto a sample surface to form plasma, and then analyzing the emitted light spectrum to identify the elemental composition of the sample. This system is ideal for material identification, classification, qualitative, and quantitative analysis.

LIBS Application’s Principle

Masic Principle

● Coal Quality Analysis and Combustion Products Analysis

● Online Component Analysis in Metallurgical Industry

● Mineral Exploration: Online Ore Quality Analysis

● Soil Heavy Metal Analysis, Biomaterials, Aerosols, Nanoparticles

● Nuclear Materials, Waste, Petroleum Products

● Building Materials, Archaeology, Casting, Gold and Jewelry Testing

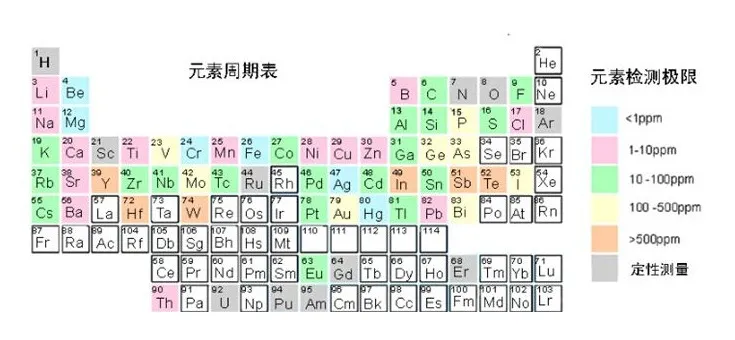

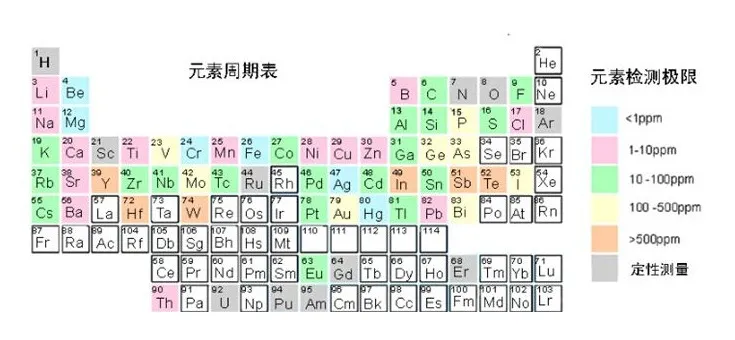

The detection limits of LIBS largely depend on the type of sample being analyzed, the specific elements being measured, and the configuration of the laser/spectrometer in the instrument. Typically, LIBS can achieve detection limits ranging from a few parts per million (ppm) to percentage levels. For most elements in common applications, the detection limit can be between 10 ppm to 100 ppm. In quantitative analysis, the relative standard deviation of measurements obtained through LIBS can be within 3-5% for most materials, and even less than 1% for homogeneous materials.

Typical Detection Limits with LIBS

● Elements like Li, Be, B, Na, Mg, Al, K, Ca: >10 ppm (0.001%)

● Elements like Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Mo: >100 ppm (0.01%)

● Elements like C, N, O, P, Si: >200 ppm (0.02%)

● Elements like F, Cl, Br, S: >0.5%

The iSpec-LIBS800 system is a comprehensive, integrated solution for performing Laser Induced Breakdown Spectroscopy, a technique used for elemental analysis of materials. This technique involves focusing ultra-short pulse lasers onto a sample surface to form plasma, and then analyzing the emitted light spectrum to identify the elemental composition of the sample. This system is ideal for material identification, classification, qualitative, and quantitative analysis.

LIBS Application’s Principle

Masic Principle

● Coal Quality Analysis and Combustion Products Analysis

● Online Component Analysis in Metallurgical Industry

● Mineral Exploration: Online Ore Quality Analysis

● Soil Heavy Metal Analysis, Biomaterials, Aerosols, Nanoparticles

● Nuclear Materials, Waste, Petroleum Products

● Building Materials, Archaeology, Casting, Gold and Jewelry Testing

The detection limits of LIBS largely depend on the type of sample being analyzed, the specific elements being measured, and the configuration of the laser/spectrometer in the instrument. Typically, LIBS can achieve detection limits ranging from a few parts per million (ppm) to percentage levels. For most elements in common applications, the detection limit can be between 10 ppm to 100 ppm. In quantitative analysis, the relative standard deviation of measurements obtained through LIBS can be within 3-5% for most materials, and even less than 1% for homogeneous materials.

Typical Detection Limits with LIBS

● Elements like Li, Be, B, Na, Mg, Al, K, Ca: >10 ppm (0.001%)

● Elements like Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Mo: >100 ppm (0.01%)

● Elements like C, N, O, P, Si: >200 ppm (0.02%)

● Elements like F, Cl, Br, S: >0.5%

Product Features and Advantages

● Wide Range of Element Analysis: Capable of analyzing light elements (like C, H, O, N, Li, Be, B) and heavy elements, including almost all metals and non-metals.

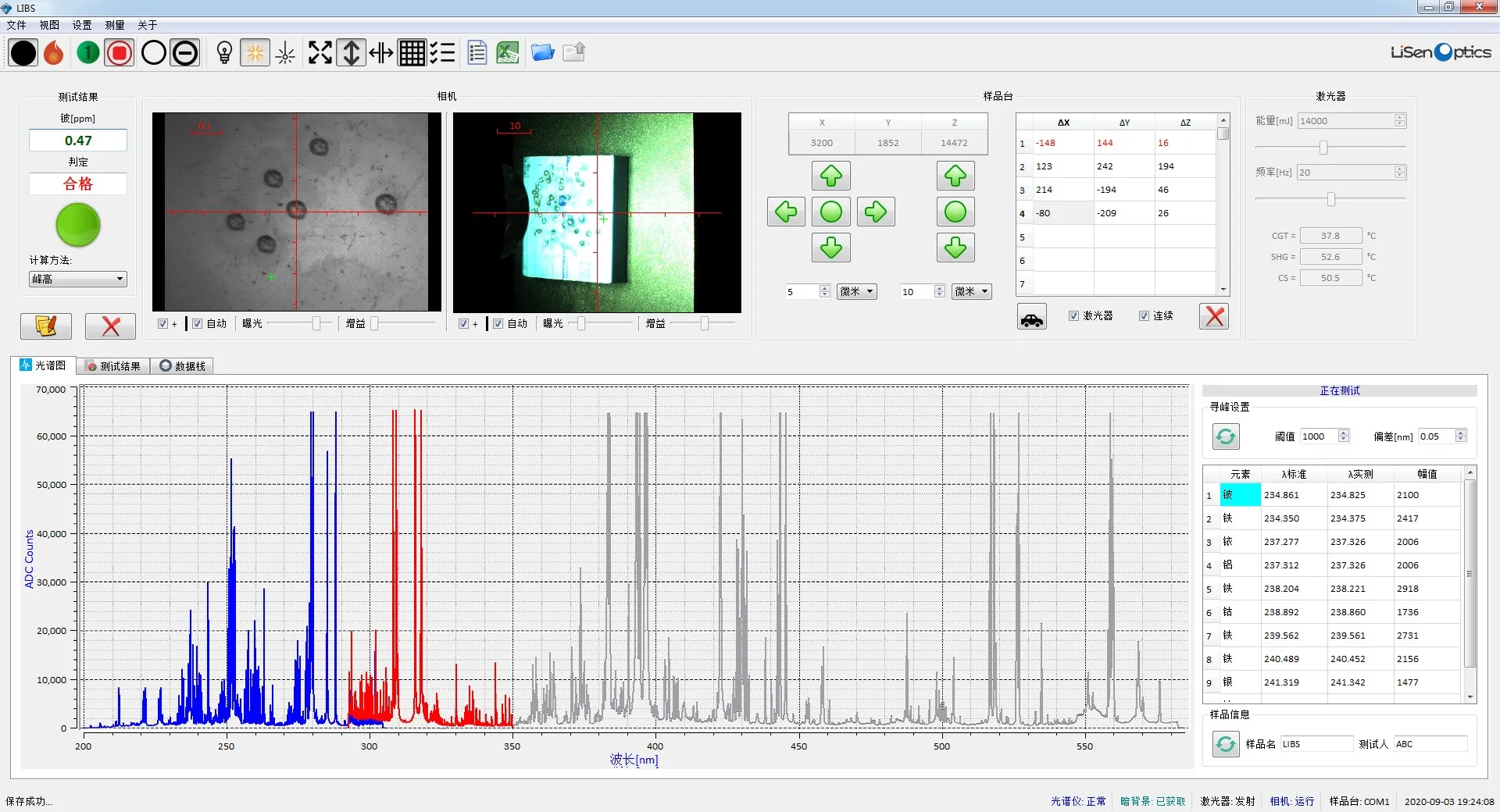

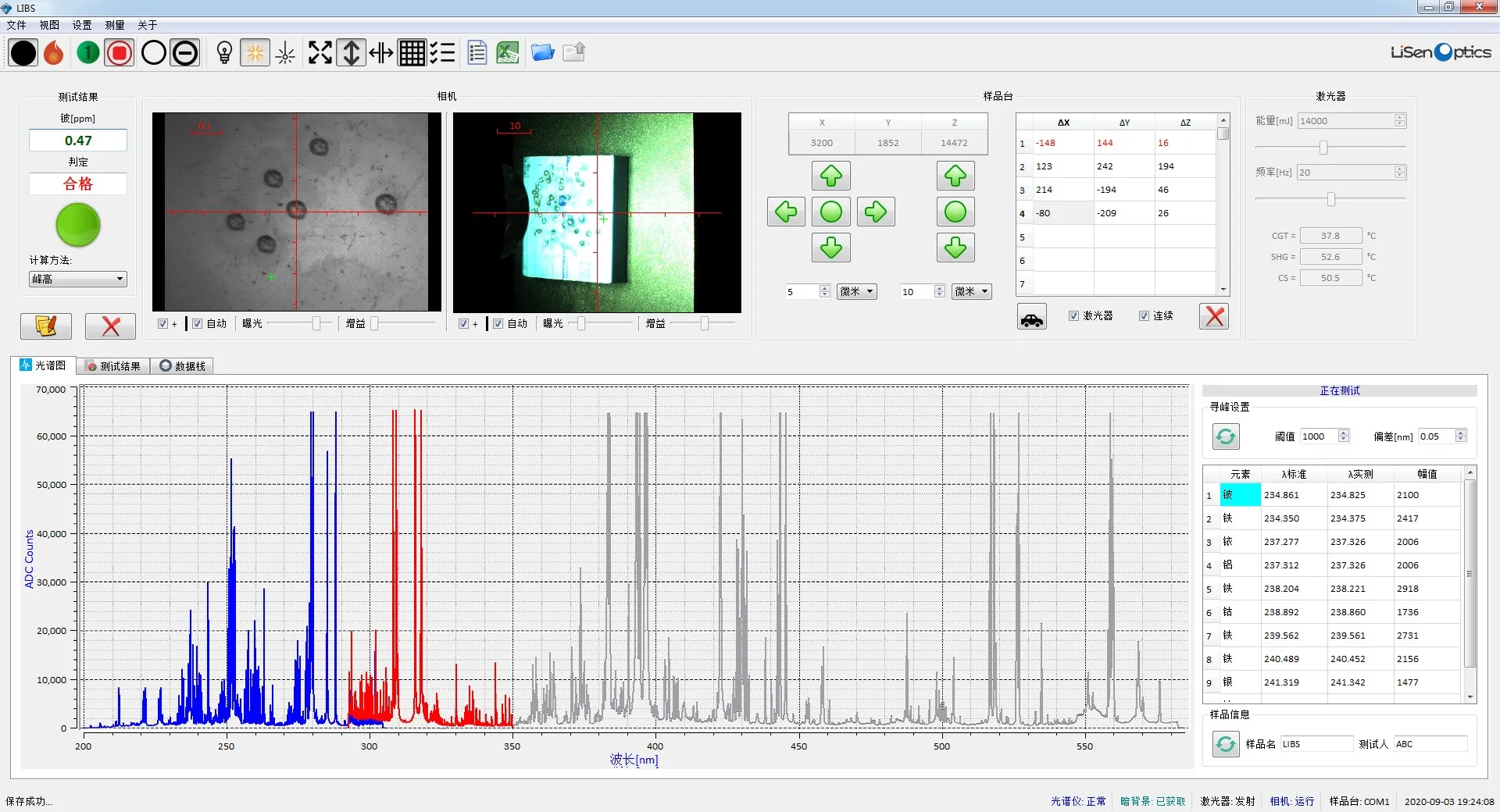

● Integrated LIBS System: Includes a laser, spectrometer, LIBS optical collection system, a 3D sample stage with linked control system, and a dual camera imaging system.

● Intelligent Spectral Collection and Analysis Software: For peak matching, online element concentration prediction, and quantitative analysis modeling (peak height method, peak area method, etc.).

● Fast Analysis Time: A few seconds to minutes.

● Minimal Sample Preparation: Analyzes solid samples, even powders (or binders or adhesives).

● Eco-Friendly and Safe: No reaction reagents required.

● Microscopic to Macroscopic Analysis: Directed and flexible point analysis.

● Qualitative and Quantitative Analysis: Sample classification and elemental concentration.

● Multiple Laser and Probe Options: To suit different needs.

● Detection Limits: Most elements have detection limits ranging from 10 ppm to several dozen ppm.

Product Features and Advantages

● Wide Range of Element Analysis: Capable of analyzing light elements (like C, H, O, N, Li, Be, B) and heavy elements, including almost all metals and non-metals.

● Integrated LIBS System: Includes a laser, spectrometer, LIBS optical collection system, a 3D sample stage with linked control system, and a dual camera imaging system.

● Intelligent Spectral Collection and Analysis Software: For peak matching, online element concentration prediction, and quantitative analysis modeling (peak height method, peak area method, etc.).

● Fast Analysis Time: A few seconds to minutes.

● Minimal Sample Preparation: Analyzes solid samples, even powders (or binders or adhesives).

● Eco-Friendly and Safe: No reaction reagents required.

● Microscopic to Macroscopic Analysis: Directed and flexible point analysis.

● Qualitative and Quantitative Analysis: Sample classification and elemental concentration.

● Multiple Laser and Probe Options: To suit different needs.

● Detection Limits: Most elements have detection limits ranging from 10 ppm to several dozen ppm.

Main Technical Indicators

|

Model |

iSpec-LIBS800 |

|

Element Measurement Range |

Atomic number Z≥1, including organic elements like C, H, O, light elements like N, Li, Be, B, and almost all metals and non-metals. |

|

Concentration Range |

1 10 ppm to percentage levels (depending on the element and instrument configuration). |

|

Analysis Time |

<30S |

|

Analysis Type |

Qualitative and quantitative. |

|

Spectrometer |

Four-channel spectrometer, wavelength λ = 190 -820nm, resolution 0.2nm; Eight-channel spectrometer, wavelength λ = 190- 1070nm, resolution 0.1nm. |

|

Laser |

Nd-YAG: 266nm wavelength, 50mJ/pulse or 1064nm wavelength, 100-200 mJ/pulse at 10Hz frequency, 5 -10ns pulse width with built-in water cooling system. |

|

Sample Window and Positioning |

XYZ three-axis automatic positioning stage, up to 5cm travel, stepper motor driven, positioning accuracy of 5 µm. |

|

Sample Imaging |

Dual lens configuration, 5x wide-angle lens for broad field observation; 400x high magnification lens for precise micro-positioning; with LED lighting. |

|

Analysis Spot Size |

Minimum focus size of 25µm |

|

LIBS Spectral Software |

Controls sample stage, laser, focusing, imaging, and other parameters. |

Main Technical Indicators

|

Model |

iSpec-LIBS800 |

|

Element Measurement Range |

Atomic number Z≥1, including organic elements like C, H, O, light elements like N, Li, Be, B, and almost all metals and non-metals. |

|

Concentration Range |

1 10 ppm to percentage levels (depending on the element and instrument configuration). |

|

Analysis Time |

<30S |

|

Analysis Type |

Qualitative and quantitative. |

|

Spectrometer |

Four-channel spectrometer, wavelength λ = 190 -820nm, resolution 0.2nm; Eight-channel spectrometer, wavelength λ = 190- 1070nm, resolution 0.1nm. |

|

Laser |

Nd-YAG: 266nm wavelength, 50mJ/pulse or 1064nm wavelength, 100-200 mJ/pulse at 10Hz frequency, 5 -10ns pulse width with built-in water cooling system. |

|

Sample Window and Positioning |

XYZ three-axis automatic positioning stage, up to 5cm travel, stepper motor driven, positioning accuracy of 5 µm. |

|

Sample Imaging |

Dual lens configuration, 5x wide-angle lens for broad field observation; 400x high magnification lens for precise micro-positioning; with LED lighting. |

|

Analysis Spot Size |

Minimum focus size of 25µm |

|

LIBS Spectral Software |

Controls sample stage, laser, focusing, imaging, and other parameters. |

Prev: no data!

Next: Modular LIBS System

Send Inquiry