Focus on spectral sensing and optoelectronic application systems

NIR Spectrometer

The LiSpec-NIR Series Near-Infrared Spectrometers are the latest flagship products in the infrared spectrometer lineup from LiSen Optics. These spectrometers are equipped with 256/512-pixel InGaAs detectors, featuring secondary semiconductor thermoelectric cooling to significantly enhance the sensitivity and signal-to-noise ratio of the near-infrared spectrometers. Additionally, the LiSpec-NIR series incorporates a unique large numerical aperture optical platform design and exclusive noise reduction low noise circuit control technology, greatly expanding the dynamic range of spectral testing. The compact optical path and structural design of the LiSpec-NIR series make these spectrometers small, slim, and versatile, ideal for laboratory setups and industrial system integration.

The LiSpec-NIR Series Near-Infrared Spectrometers are the latest flagship products in the infrared spectrometer lineup from LiSen Optics. These spectrometers are equipped with 256/512-pixel InGaAs detectors, featuring secondary semiconductor thermoelectric cooling to significantly enhance the sensitivity and signal-to-noise ratio of the near-infrared spectrometers. Additionally, the LiSpec-NIR series incorporates a unique large numerical aperture optical platform design and exclusive noise reduction low noise circuit control technology, greatly expanding the dynamic range of spectral testing. The compact optical path and structural design of the LiSpec-NIR series make these spectrometers small, slim, and versatile, ideal for laboratory setups and industrial system integration.

Product Introduction

|

|

The LiSpec-NIR series offers a replaceable slit design, allowing a single spectrometer to be equipped with slits of various widths to meet different spectral measurement needs in terms of resolution and sensitivity. This flexibility expands its applicability to areas such as freshness and sugar content detection in vegetables, component analysis in oils, pharmaceutical component analysis and process monitoring, material screening, and quality control. Due to its compact structure, excellent consistency, good thermal stability, reliability, low stray light characteristics, and the shortest integration time of up to 6 microseconds for high-speed measurements, it supports USB and RS-232 communication, with strong anti-interference capabilities. This makes it highly suitable for industrial process control, petrochemicals, food sorting, biopharmaceuticals, and life sciences.

Technical Advantages and Features

● Spectral range of 900-1700nm/1000-2500nm, with the ability to change slits freely for flexible expansion.

● The detector uses 256/512-pixel InGaAs with secondary semiconductor thermoelectric cooling, ensuring high thermal stability and reliability.

● Large numerical aperture optical platform design and unique noise reduction circuit control technology enhance sensitivity and signal-to-noise ratio, offering a wide testing dynamic range.

● Small, slim, and versatile design facilitates ease of integration into laboratories or industrial systems.

● LiSpecView full-featured spectral testing software provides a variety of functional measurements including transmission, absolute radiation, Raman, absorbance, laser power, and color measurement.

|

|

The LiSpec-NIR series offers a replaceable slit design, allowing a single spectrometer to be equipped with slits of various widths to meet different spectral measurement needs in terms of resolution and sensitivity. This flexibility expands its applicability to areas such as freshness and sugar content detection in vegetables, component analysis in oils, pharmaceutical component analysis and process monitoring, material screening, and quality control. Due to its compact structure, excellent consistency, good thermal stability, reliability, low stray light characteristics, and the shortest integration time of up to 6 microseconds for high-speed measurements, it supports USB and RS-232 communication, with strong anti-interference capabilities. This makes it highly suitable for industrial process control, petrochemicals, food sorting, biopharmaceuticals, and life sciences.

Technical Advantages and Features

● Spectral range of 900-1700nm/1000-2500nm, with the ability to change slits freely for flexible expansion.

● The detector uses 256/512-pixel InGaAs with secondary semiconductor thermoelectric cooling, ensuring high thermal stability and reliability.

● Large numerical aperture optical platform design and unique noise reduction circuit control technology enhance sensitivity and signal-to-noise ratio, offering a wide testing dynamic range.

● Small, slim, and versatile design facilitates ease of integration into laboratories or industrial systems.

● LiSpecView full-featured spectral testing software provides a variety of functional measurements including transmission, absolute radiation, Raman, absorbance, laser power, and color measurement.

Main Technical Indicators

|

Model |

LiSpec-Mini-NIR4000 (Pro) |

LiSpec-CMC-NIR4000 (Pro) |

|

Miniature Non-Cooled NIR Spectrometer |

Non-Cooled NIR Spectrometer |

|

|

Pic. |

|

|

|

Spectral Range |

900–1700 nm |

900–1700 nm |

|

Optical Resolution (FWHM) |

5–15 nm |

5–15 nm |

|

Wavelength Accuracy |

≤ ±0.5 nm |

≤ ±0.5 nm |

|

Stray Light |

< 0.2% |

< 0.2% |

|

Detector |

Linear array 128/256-pixel InGaAs |

Linear array 128/256-pixel InGaAs |

|

Signal-to-Noise Ratio |

6500:01:00 |

6000:01:00 |

|

Dynamic Range |

9000:01:00 |

7000:01:00 |

|

Dark Noise (RMS) |

8 counts |

15 counts |

|

AD Conversion |

16-bit, 15 MHz |

16-bit, 15 MHz |

|

Integration Time |

6 μs–24 s |

100 μs–15 s |

|

Communication Interface |

USB 2.0 / 8Pin GPIO |

USB 2.0 / 8Pin GPIO |

|

I/O Interface |

8Pin GPIO |

8Pin GPIO |

|

Power Supply |

500 mA / 5 VDC, USB default power |

500 mA / 5 VDC, USB default power |

|

Operating Temperature |

0–55°C |

0–55°C |

|

Dimensions / Weight |

51 × 36 × 29 mm |

65 × 65 × 30 mm |

Spectrometer’s Resolution Selection Table

|

LiSpec-Mini-NIR4000(Pro) |

|||||||||

|

No. |

Wavelength Range(nm) |

Grating wavelength coverage range(nm) |

Grating |

Slit Width(μm) |

|||||

|

10 |

25 |

50 |

100 |

200 |

|||||

|

Resolution(nm) |

|||||||||

|

1 |

900-1400 |

500 |

300 g/mm |

7 |

12 |

15 |

20 |

35 |

|

|

2 |

900-1700 |

800 |

360 g/mm |

6 |

10 |

11 |

17 |

30 |

|

|

LiSpec-CMC-NIR4000(Pro) |

|||||||||

|

No. |

Wavelength Range(nm) |

Grating wavelength coverage range(nm) |

Grating |

Slit Width(μm) |

|||||

|

50 |

100 |

200 |

|||||||

|

Resolution(nm) |

|||||||||

|

1 |

900-1700 |

800 |

150 g/mm |

11 |

22 |

30 |

|||

|

2 |

900-1700 |

800 |

300 g/mm |

6 |

10 |

15 |

|||

Main Technical Indicators

|

Model |

LiSpec-Mini-NIR4000 (Pro) |

LiSpec-CMC-NIR4000 (Pro) |

|

Miniature Non-Cooled NIR Spectrometer |

Non-Cooled NIR Spectrometer |

|

|

Pic. |

|

|

|

Spectral Range |

900–1700 nm |

900–1700 nm |

|

Optical Resolution (FWHM) |

5–15 nm |

5–15 nm |

|

Wavelength Accuracy |

≤ ±0.5 nm |

≤ ±0.5 nm |

|

Stray Light |

< 0.2% |

< 0.2% |

|

Detector |

Linear array 128/256-pixel InGaAs |

Linear array 128/256-pixel InGaAs |

|

Signal-to-Noise Ratio |

6500:01:00 |

6000:01:00 |

|

Dynamic Range |

9000:01:00 |

7000:01:00 |

|

Dark Noise (RMS) |

8 counts |

15 counts |

|

AD Conversion |

16-bit, 15 MHz |

16-bit, 15 MHz |

|

Integration Time |

6 μs–24 s |

100 μs–15 s |

|

Communication Interface |

USB 2.0 / 8Pin GPIO |

USB 2.0 / 8Pin GPIO |

|

I/O Interface |

8Pin GPIO |

8Pin GPIO |

|

Power Supply |

500 mA / 5 VDC, USB default power |

500 mA / 5 VDC, USB default power |

|

Operating Temperature |

0–55°C |

0–55°C |

|

Dimensions / Weight |

51 × 36 × 29 mm |

65 × 65 × 30 mm |

Spectrometer’s Resolution Selection Table

|

LiSpec-Mini-NIR4000(Pro) |

|||||||||

|

No. |

Wavelength Range(nm) |

Grating wavelength coverage range(nm) |

Grating |

Slit Width(μm) |

|||||

|

10 |

25 |

50 |

100 |

200 |

|||||

|

Resolution(nm) |

|||||||||

|

1 |

900-1400 |

500 |

300 g/mm |

7 |

12 |

15 |

20 |

35 |

|

|

2 |

900-1700 |

800 |

360 g/mm |

6 |

10 |

11 |

17 |

30 |

|

|

LiSpec-CMC-NIR4000(Pro) |

|||||||||

|

No. |

Wavelength Range(nm) |

Grating wavelength coverage range(nm) |

Grating |

Slit Width(μm) |

|||||

|

50 |

100 |

200 |

|||||||

|

Resolution(nm) |

|||||||||

|

1 |

900-1700 |

800 |

150 g/mm |

11 |

22 |

30 |

|||

|

2 |

900-1700 |

800 |

300 g/mm |

6 |

10 |

15 |

|||

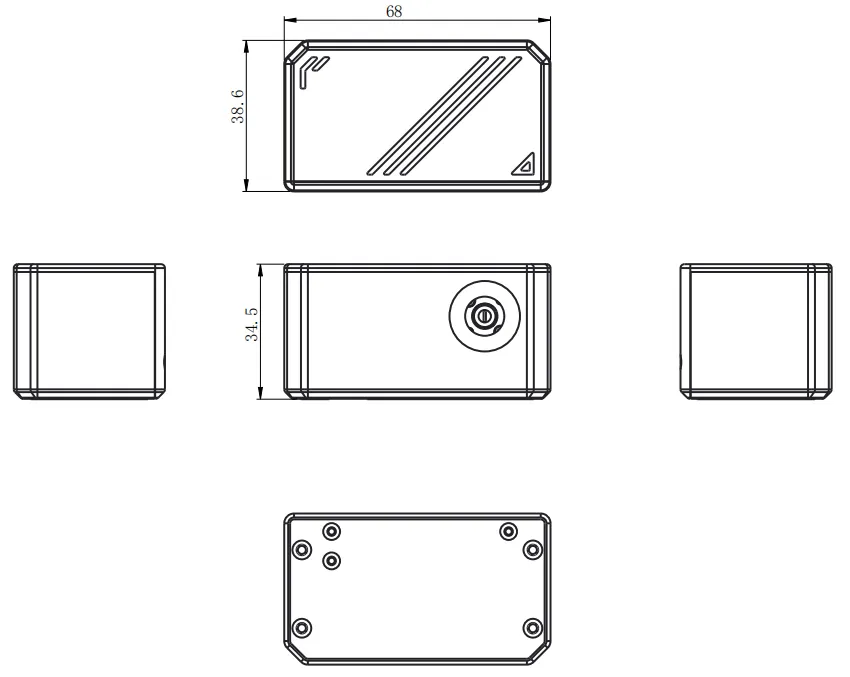

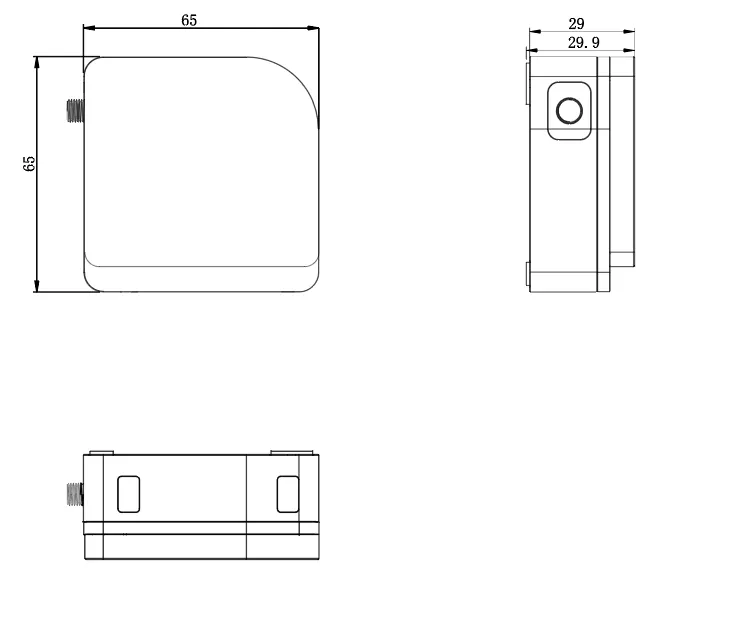

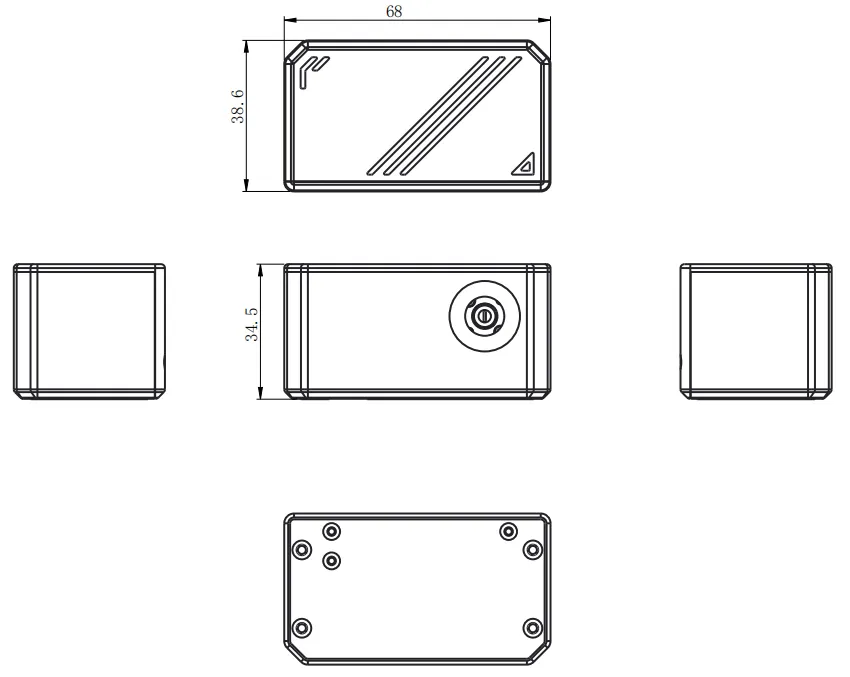

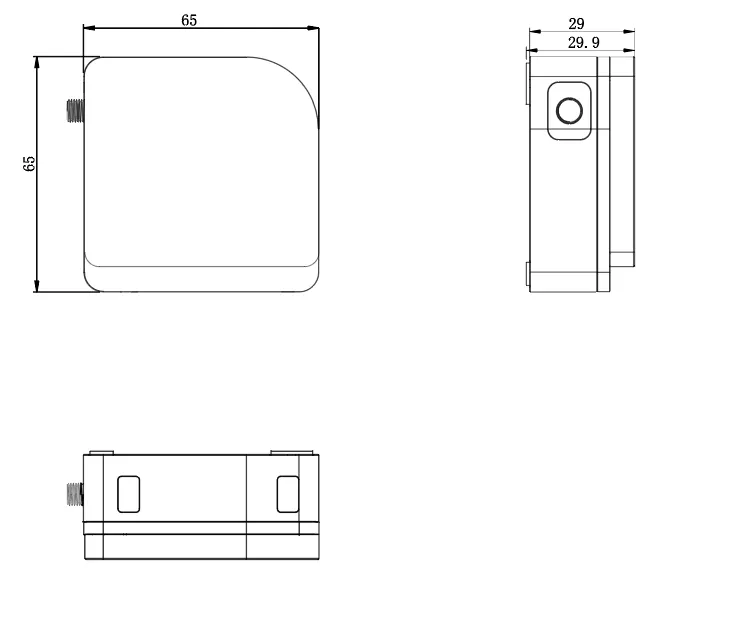

Dimension (Unit: mm)

● LiSpec-Mini-NIR4000(Pro)

● LiSpec-CMC-NIR4000(Pro)

Note: Specialized Wavelength Range Can be Customized

Typical Application

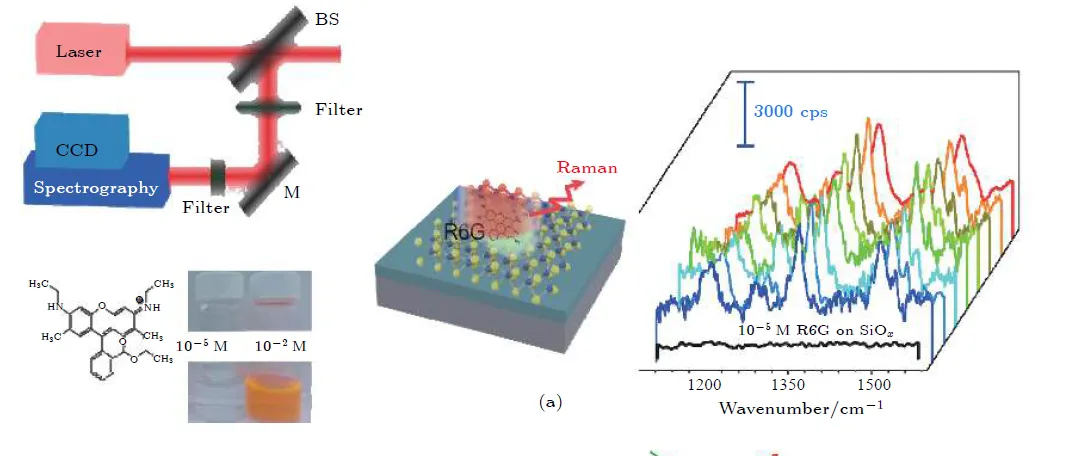

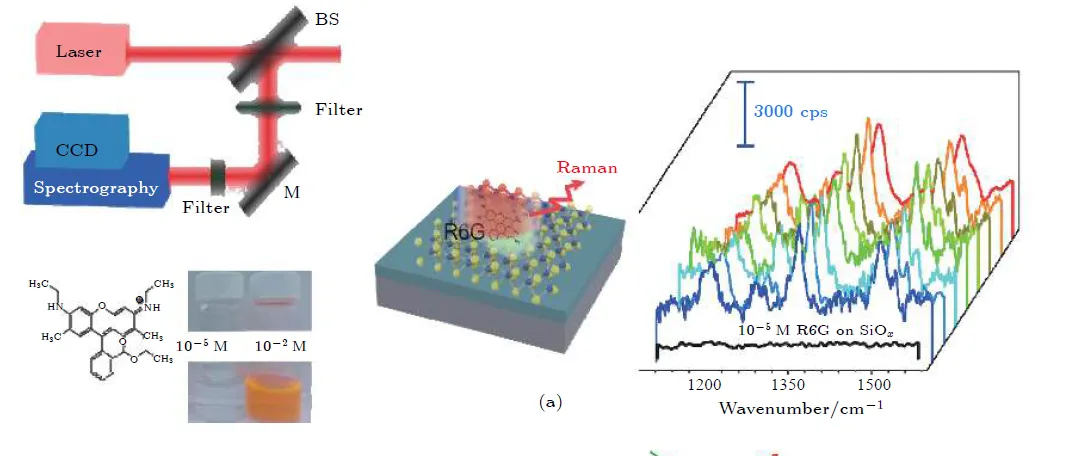

● Raman Spectroscopy Measurement

The Raman measurement system mainly consists of a spectrometer, a laser, a Raman probe, and Raman identification spectrum analysis software. Raman scattering is primarily Stokes and anti-Stokes, with Stokes Raman scattering usually much stronger than anti-Stokes scattering. Raman spectrometers typically measure Stokes scattering. Commonly used Raman spectrometers include 532/785/1064 Raman spectrometers. Raman measurements are generally an order of magnitude weaker than fluorescence signals. For weak Raman signal measurements, Surface-Enhanced Raman Scattering (SERS) is employed to amplify the Raman signal. LiSen Optics' LiSpec-UV series of industrial high-speed spectrometers, with their high sensitivity and high signal-to-noise ratio, can be paired with lasers and Raman probes to measure weak spectral signals, widely used in food safety, chemical laboratories, biology, and medical optics for the determination and confirmation of substance composition. They are also applicable in forensics for drug detection and in the jewelry industry for gemstone identification.

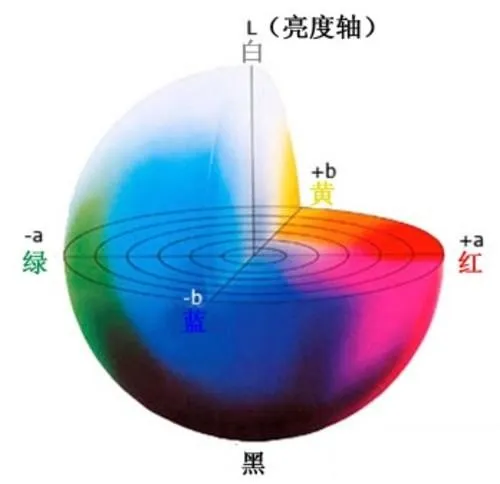

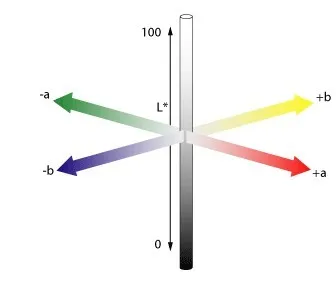

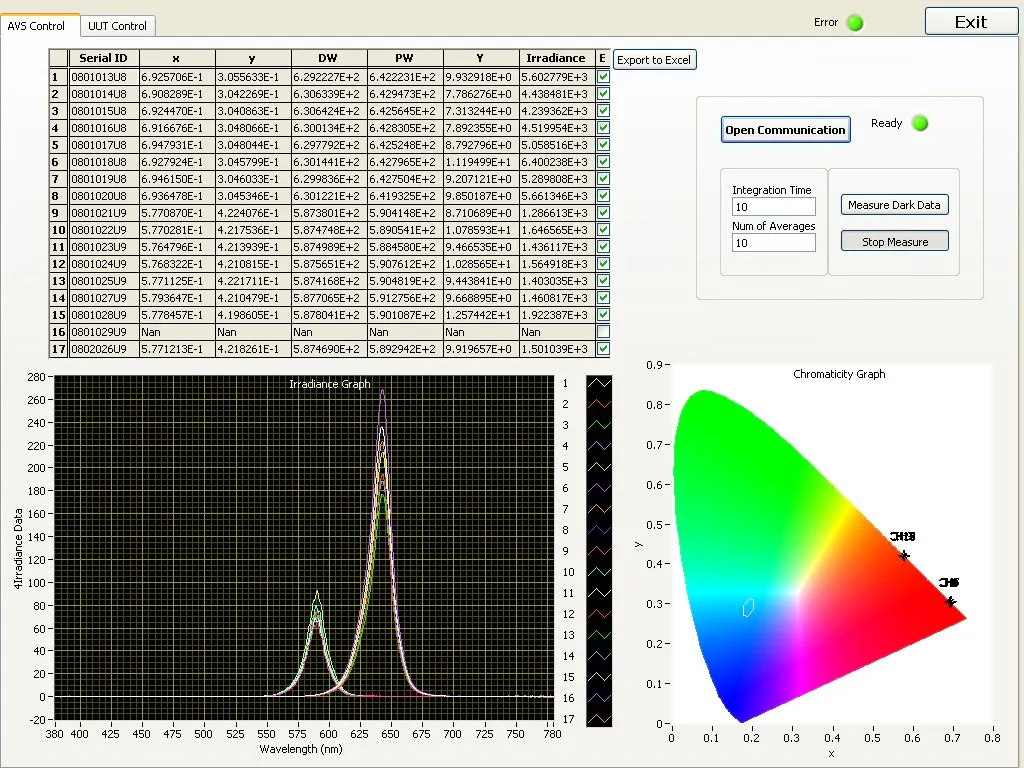

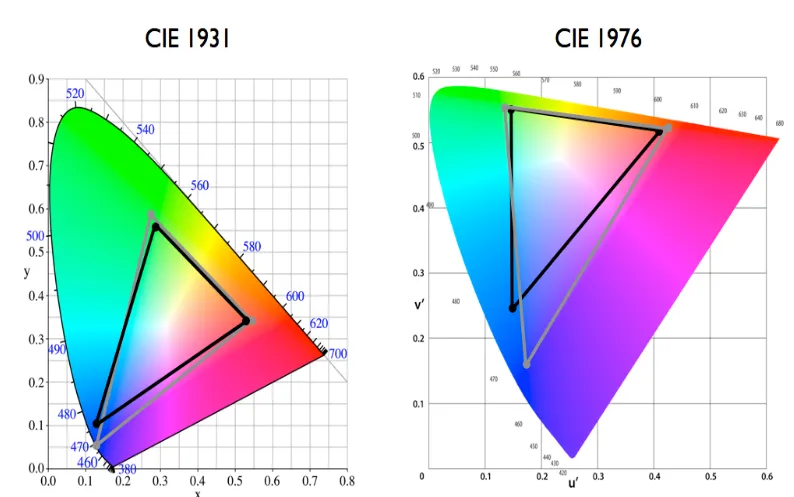

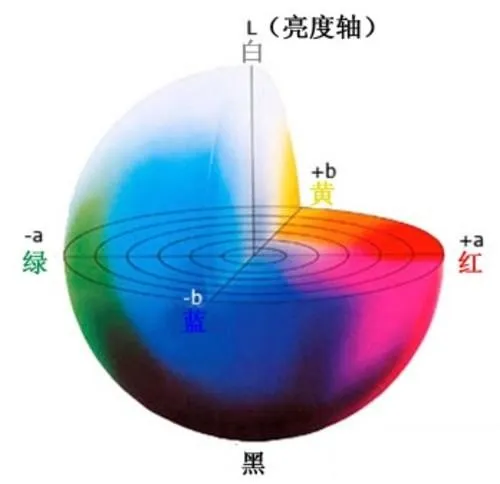

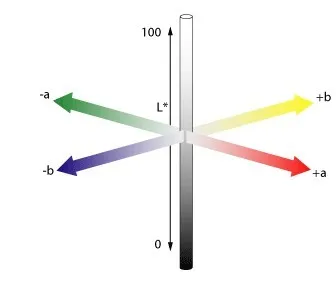

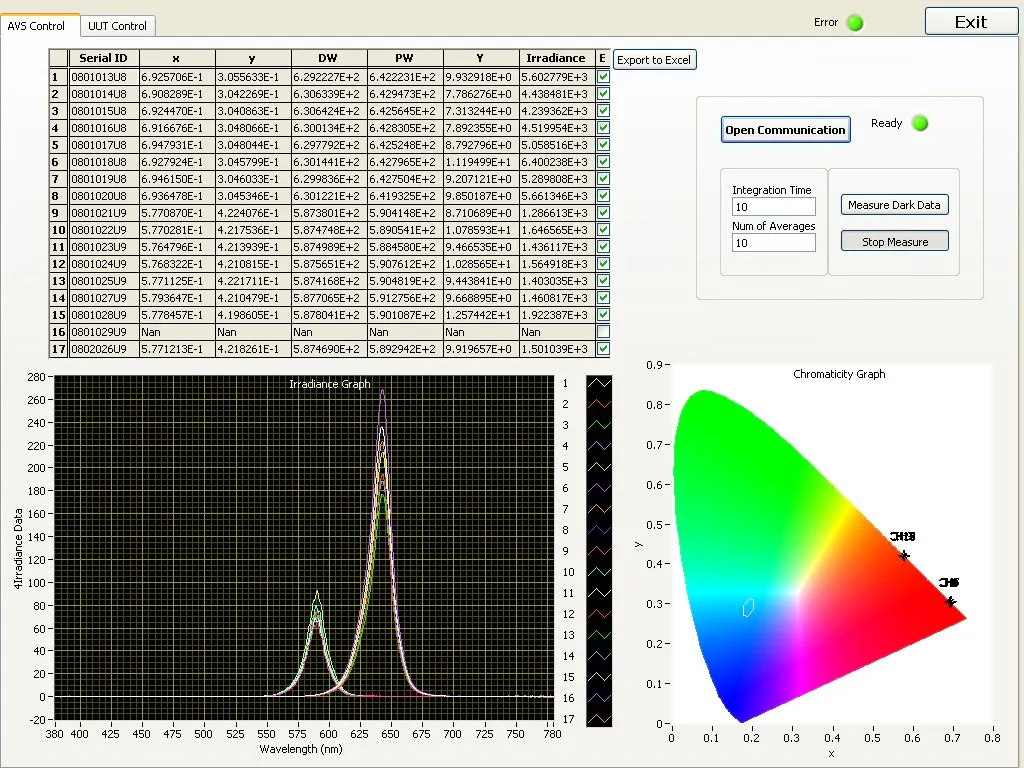

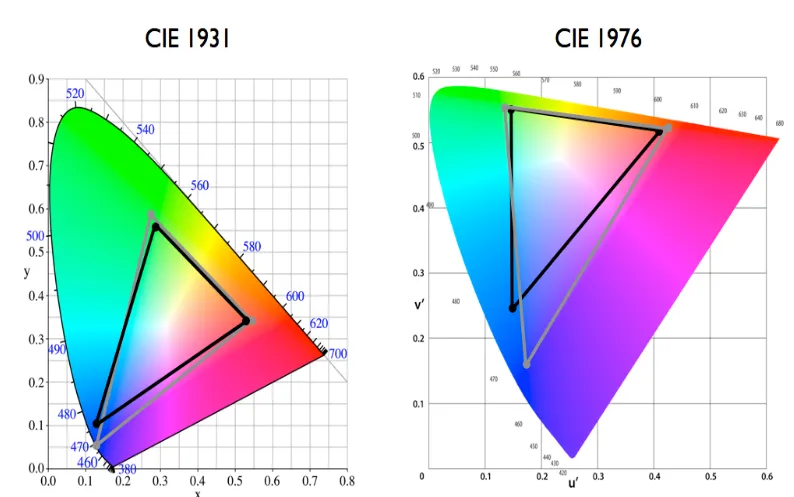

● Color Measurement

The color of an object can be described by the CIE1976 (Lab*) color space. L* represents the brightness of the color, positive a* values represent red, negative a* values represent green, hue, and chroma. Similarly, positive b* values represent yellow, and negative b* values represent blue. Lab* values can be derived from the CIE tristimulus values X, Y, Z of the sample (object) and the tristimulus values Xn, Yn, Zn of the standard light source. The tristimulus values X, Y, Z of an object's color are obtained by multiplying the relative power P of the standard light source, the reflectance R (or transmittance T) of the object, and the CIE standard observer functions Xλ,yλ,zλ (for 2 or 10-degree fields). Integrating these values over the visible spectrum range (from 380 to 780 nm, at 5 nm intervals) yields the tristimulus values. Professional color measurement software can compare the measured Lab* values with reference colors to calculate the color difference(△Elab,△L*,△a*,△b*).

|

|

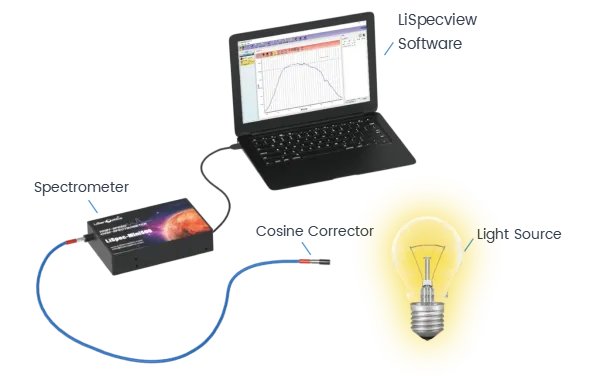

● Radiation Measurement

Radiant light energy can be quantified as radiant flux, which is a standard measure of the energy radiated per second (W) from a light source. Radiation measurements generally require absolute radiometric calibration of the spectrometer system with a standard light source of known spectral energy distribution. This calibration allows for radiation measurements through quantifiable parameters. Radiation energy related to human vision (photometry) can obtain the spectral luminous efficiency functions defined by the CIE, which represent the average vision of observers. Therefore, radiometric parameters, photometric parameters, and colorimetric parameters are defined in radiation measurement. Radiometric parameters mainly include irradiance μW/cm², radiance µWatt/sr, radiant flux µWatt, and photon count µMol/s/m², µMol/m², µMol/s, and µMol. Photometric parameters include lumens, illuminance Lux, and intensity Candela. Colorimetric parameters include X, Y, Z, x, y, z, u, v, color temperature, CRI color rendering index, etc.

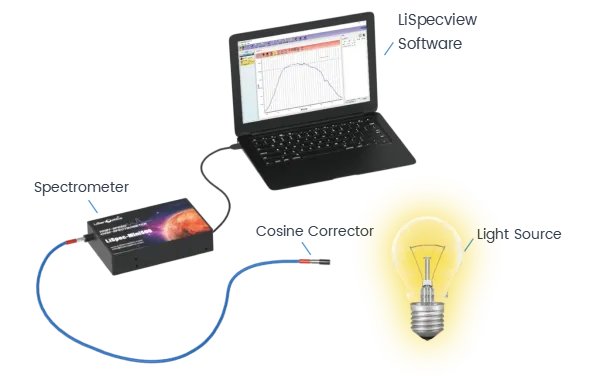

● Irradiance Measurement

● LED Color Measurement

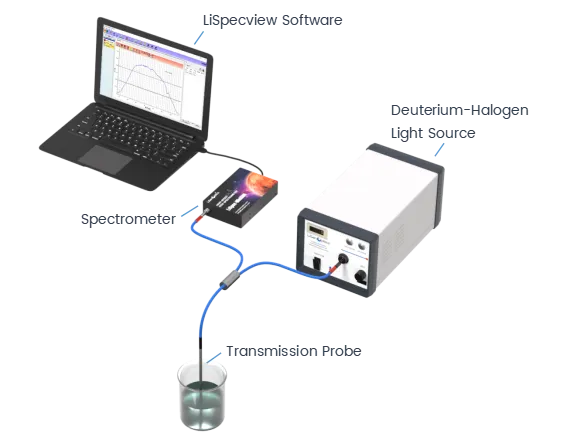

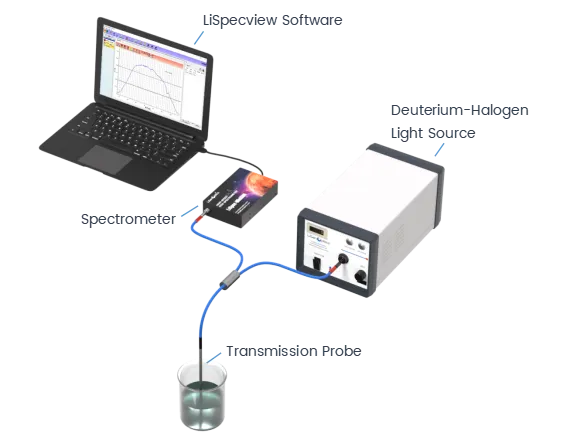

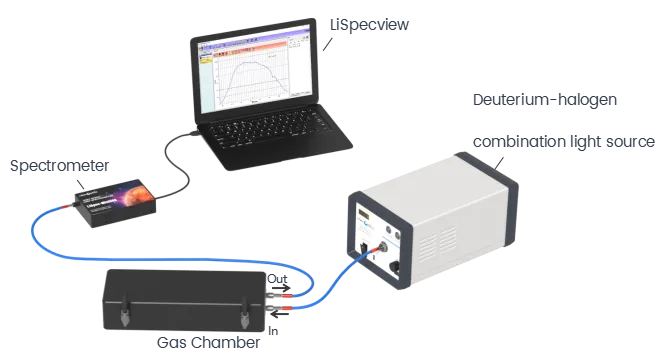

● Absorbance Measurement

The method of measuring absorbance with a spectrometer involves passing parallel light of a certain wavelength through a flat parallel sample and detecting the light transmitted through the sample. Since a portion of the energy is absorbed by molecules in the sample, the intensity of the detected incident light is higher than that transmitted through the sample. Absorbance is widely used in spectral measurement techniques for liquids and gases for quantitative identification of substances or fingerprint authentication. It can also be integrated into industrial applications and tests of interest to customers. Using LiSen Optics' modular spectrometers, specific absorbance measurements can be selected based on different wavelength ranges and resolutions. In the lab or field, the entire optical measurement setup can be quickly configured. Based on the high-quality spectrometers from LiSen Optics, a flexible and easy-to-use combination can be made by choosing UV light sources, different optical path gas chambers, absorption cells, specific absorption path modules, and fiber probes, offering a variety of configuration options for different absorbance test

● Liquid Absorbance

Absorbance Measurement (Cuvette)

Absorbance Measurement (Fiber Probe)

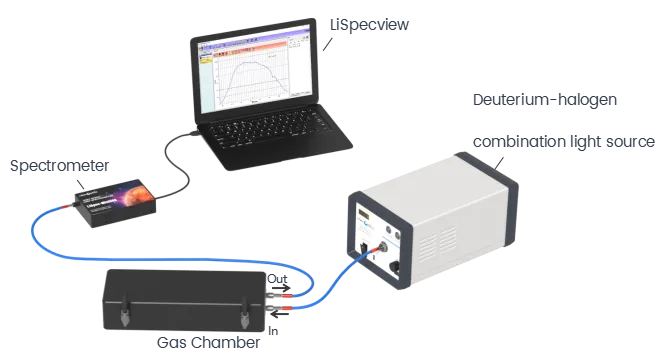

● Gas Absorbance

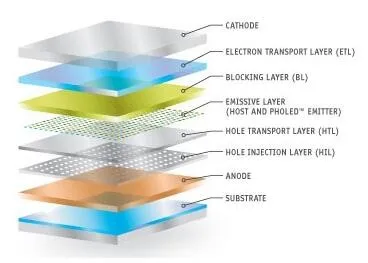

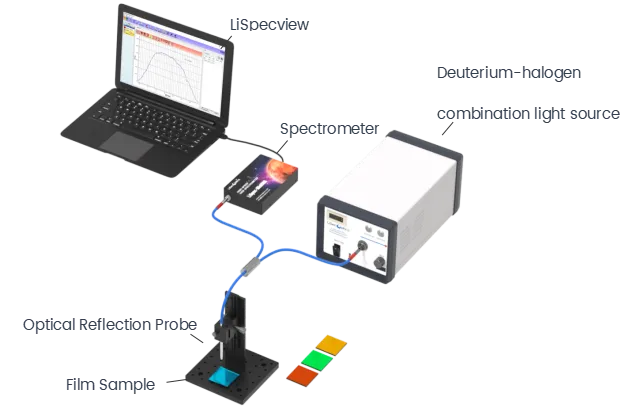

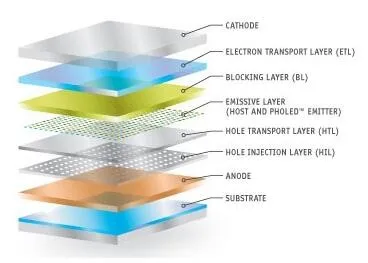

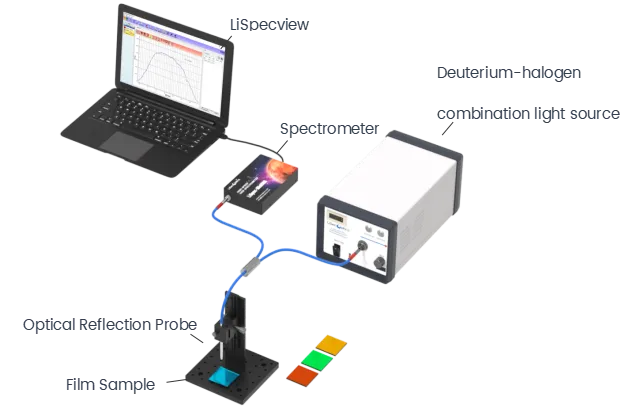

● Thin Film Measurement

Thin film measurement systems are based on the principle of white light interferometry to determine the thickness of optical thin films. The thickness of the film is calculated through mathematical functions applied to the white light interference patterns. For a single-layer film, the physical thickness can be calculated if the refractive index (n) and extinction coefficient (k) of the film medium are known. The measurable film thickness ranges from 10 nm to 50 µm, with a resolution of up to 1 nm. Thin film measurement is applied in the semiconductor chip production industry, where it is necessary to monitor plasma etching and deposition processes. It can also be used in other fields requiring measurement of transparent film layers deposited on metal and glass substrates, such as transparent coatings on metal surfaces and glass substrates.

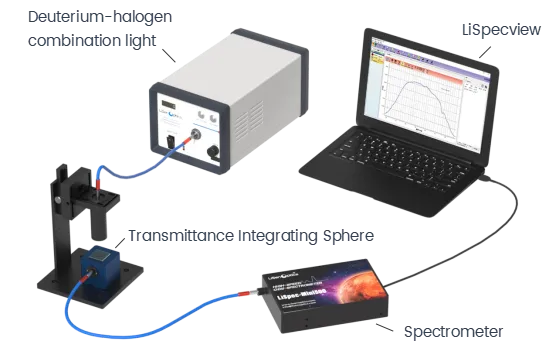

● Transmission/Reflection Spectral Measurement

With the booming industrial development, the quality control of the material characteristics has become increasingly strict. The technology of rapid and accurate transmission/reflection spectral measurements using fiber optic spectrometers is becoming more mature. Transmission/reflection spectral measurement is a basic method of spectral measurement, typically requiring equipment such as a spectrometer, light source, optical fiber, measurement stand, standard reference samples, and measurement software. To obtain better spectral data from different types of samples, these two basic modes may evolve into many more forms. Fiber optic spectrometers use optical fiber paths, overcoming the limitations of optical paths in instrument integration. LiSen Optics' fiber optic spectrometers are characterized by their small size, high stability, support for secondary software development, and a rich array of accessories, and have been successfully applied in the testing of industries such as glass and polymer materials. LiSen Optics provides users with spectral measurement equipment centered around spectrometers, and with these richly configured devices, various common spectral measurement systems can be easily set up.

Dimension (Unit: mm)

● LiSpec-Mini-NIR4000(Pro)

● LiSpec-CMC-NIR4000(Pro)

Note: Specialized Wavelength Range Can be Customized

Typical Application

● Raman Spectroscopy Measurement

The Raman measurement system mainly consists of a spectrometer, a laser, a Raman probe, and Raman identification spectrum analysis software. Raman scattering is primarily Stokes and anti-Stokes, with Stokes Raman scattering usually much stronger than anti-Stokes scattering. Raman spectrometers typically measure Stokes scattering. Commonly used Raman spectrometers include 532/785/1064 Raman spectrometers. Raman measurements are generally an order of magnitude weaker than fluorescence signals. For weak Raman signal measurements, Surface-Enhanced Raman Scattering (SERS) is employed to amplify the Raman signal. LiSen Optics' LiSpec-UV series of industrial high-speed spectrometers, with their high sensitivity and high signal-to-noise ratio, can be paired with lasers and Raman probes to measure weak spectral signals, widely used in food safety, chemical laboratories, biology, and medical optics for the determination and confirmation of substance composition. They are also applicable in forensics for drug detection and in the jewelry industry for gemstone identification.

● Color Measurement

The color of an object can be described by the CIE1976 (Lab*) color space. L* represents the brightness of the color, positive a* values represent red, negative a* values represent green, hue, and chroma. Similarly, positive b* values represent yellow, and negative b* values represent blue. Lab* values can be derived from the CIE tristimulus values X, Y, Z of the sample (object) and the tristimulus values Xn, Yn, Zn of the standard light source. The tristimulus values X, Y, Z of an object's color are obtained by multiplying the relative power P of the standard light source, the reflectance R (or transmittance T) of the object, and the CIE standard observer functions Xλ,yλ,zλ (for 2 or 10-degree fields). Integrating these values over the visible spectrum range (from 380 to 780 nm, at 5 nm intervals) yields the tristimulus values. Professional color measurement software can compare the measured Lab* values with reference colors to calculate the color difference(△Elab,△L*,△a*,△b*).

|

|

● Radiation Measurement

Radiant light energy can be quantified as radiant flux, which is a standard measure of the energy radiated per second (W) from a light source. Radiation measurements generally require absolute radiometric calibration of the spectrometer system with a standard light source of known spectral energy distribution. This calibration allows for radiation measurements through quantifiable parameters. Radiation energy related to human vision (photometry) can obtain the spectral luminous efficiency functions defined by the CIE, which represent the average vision of observers. Therefore, radiometric parameters, photometric parameters, and colorimetric parameters are defined in radiation measurement. Radiometric parameters mainly include irradiance μW/cm², radiance µWatt/sr, radiant flux µWatt, and photon count µMol/s/m², µMol/m², µMol/s, and µMol. Photometric parameters include lumens, illuminance Lux, and intensity Candela. Colorimetric parameters include X, Y, Z, x, y, z, u, v, color temperature, CRI color rendering index, etc.

● Irradiance Measurement

● LED Color Measurement

● Absorbance Measurement

The method of measuring absorbance with a spectrometer involves passing parallel light of a certain wavelength through a flat parallel sample and detecting the light transmitted through the sample. Since a portion of the energy is absorbed by molecules in the sample, the intensity of the detected incident light is higher than that transmitted through the sample. Absorbance is widely used in spectral measurement techniques for liquids and gases for quantitative identification of substances or fingerprint authentication. It can also be integrated into industrial applications and tests of interest to customers. Using LiSen Optics' modular spectrometers, specific absorbance measurements can be selected based on different wavelength ranges and resolutions. In the lab or field, the entire optical measurement setup can be quickly configured. Based on the high-quality spectrometers from LiSen Optics, a flexible and easy-to-use combination can be made by choosing UV light sources, different optical path gas chambers, absorption cells, specific absorption path modules, and fiber probes, offering a variety of configuration options for different absorbance test

● Liquid Absorbance

Absorbance Measurement (Cuvette)

Absorbance Measurement (Fiber Probe)

● Gas Absorbance

● Thin Film Measurement

Thin film measurement systems are based on the principle of white light interferometry to determine the thickness of optical thin films. The thickness of the film is calculated through mathematical functions applied to the white light interference patterns. For a single-layer film, the physical thickness can be calculated if the refractive index (n) and extinction coefficient (k) of the film medium are known. The measurable film thickness ranges from 10 nm to 50 µm, with a resolution of up to 1 nm. Thin film measurement is applied in the semiconductor chip production industry, where it is necessary to monitor plasma etching and deposition processes. It can also be used in other fields requiring measurement of transparent film layers deposited on metal and glass substrates, such as transparent coatings on metal surfaces and glass substrates.

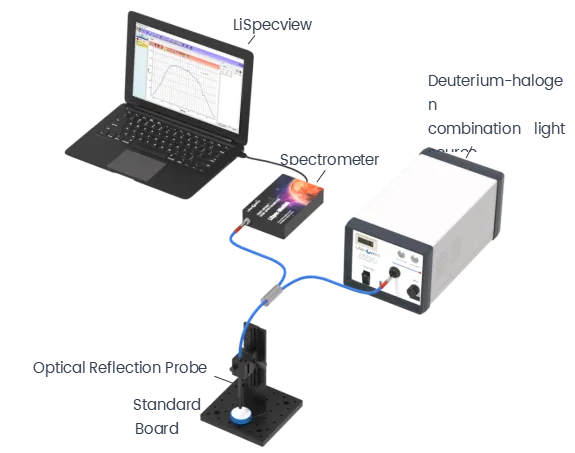

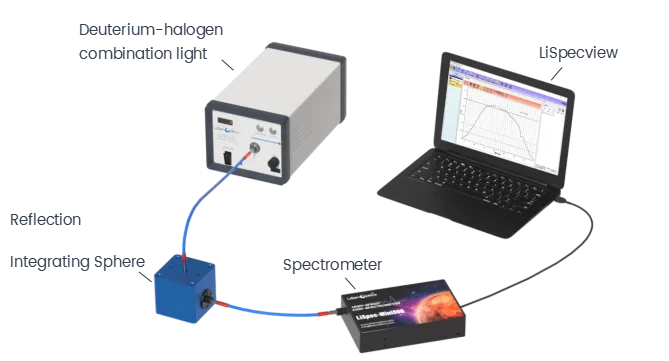

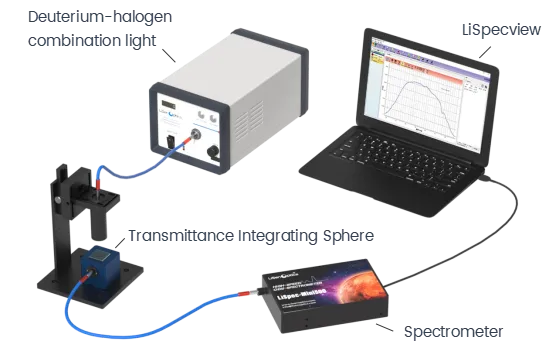

● Transmission/Reflection Spectral Measurement

With the booming industrial development, the quality control of the material characteristics has become increasingly strict. The technology of rapid and accurate transmission/reflection spectral measurements using fiber optic spectrometers is becoming more mature. Transmission/reflection spectral measurement is a basic method of spectral measurement, typically requiring equipment such as a spectrometer, light source, optical fiber, measurement stand, standard reference samples, and measurement software. To obtain better spectral data from different types of samples, these two basic modes may evolve into many more forms. Fiber optic spectrometers use optical fiber paths, overcoming the limitations of optical paths in instrument integration. LiSen Optics' fiber optic spectrometers are characterized by their small size, high stability, support for secondary software development, and a rich array of accessories, and have been successfully applied in the testing of industries such as glass and polymer materials. LiSen Optics provides users with spectral measurement equipment centered around spectrometers, and with these richly configured devices, various common spectral measurement systems can be easily set up.

● Reflectance Measurement

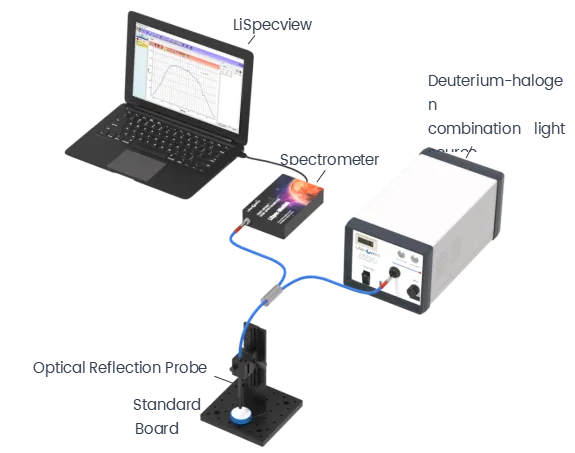

Reflectance Measurement(Probe)

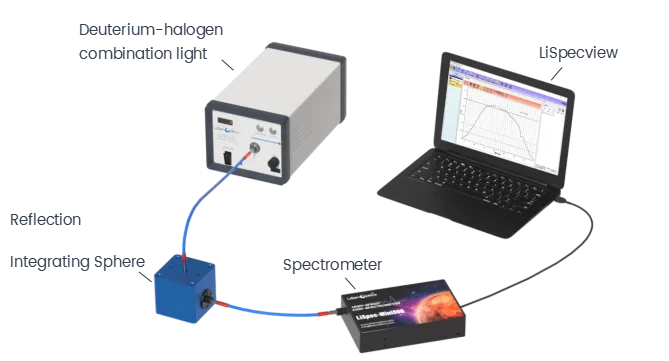

Reflectance Measurement (Integrating Sphere)

● Transmittance Measurement

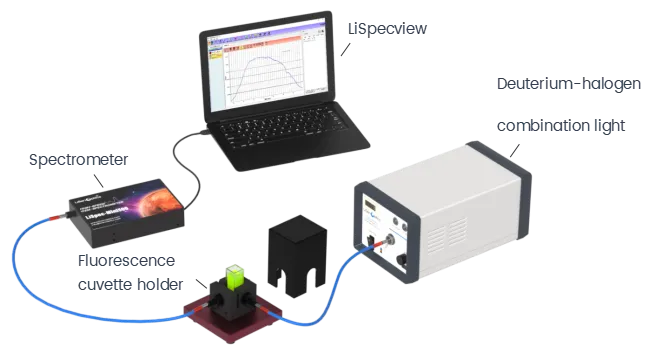

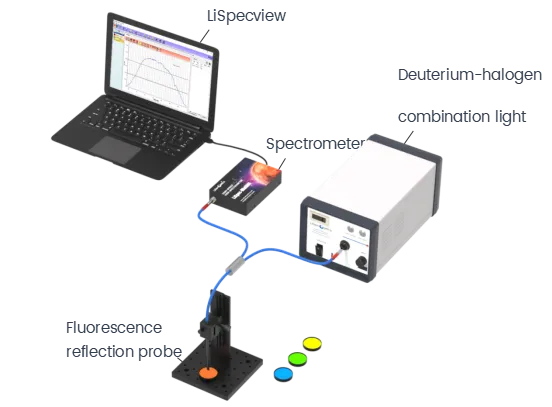

● Fluorescence Spectral Measurement

Fluorescent substances emit radiation with a certain spectral distribution under the radiation energy of specific wavelengths, usually scattering energy radiation in all directions. The fluorescence energy generated in fluorescence spectral measurement is less than the energy of the photons of the excitation light, only about 3% of the excitation light energy. It has high sensitivity, strong selectivity, requires small sample quantities, is simple to use, and is environmentally friendly. It is widely used in engineering applications such as monitoring food safety in food processing, fluorescence diagnosis of lesions in biomedical applications, exploration of oil minerals in geology, determination of soil mineral composition, and detection of trace elements in substances. LiSen Optics' fiber optic spectrometers feature interchangeable slits, selectable wavelength ranges, and resolution design, allowing customers to freely configure and match the fluorescence measurement system with suitable parameters according to their needs.

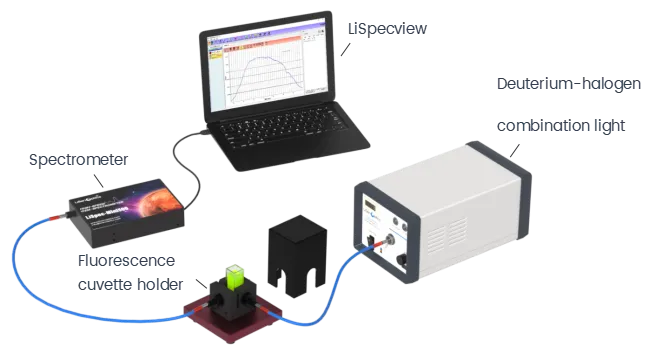

Fluorescence Measurement (Liquid)

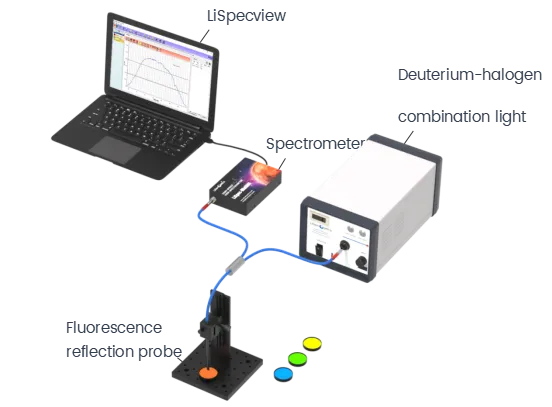

Fluorescence Measurement (Powder, Solid)

● Reflectance Measurement

Reflectance Measurement(Probe)

Reflectance Measurement (Integrating Sphere)

● Transmittance Measurement

● Fluorescence Spectral Measurement

Fluorescent substances emit radiation with a certain spectral distribution under the radiation energy of specific wavelengths, usually scattering energy radiation in all directions. The fluorescence energy generated in fluorescence spectral measurement is less than the energy of the photons of the excitation light, only about 3% of the excitation light energy. It has high sensitivity, strong selectivity, requires small sample quantities, is simple to use, and is environmentally friendly. It is widely used in engineering applications such as monitoring food safety in food processing, fluorescence diagnosis of lesions in biomedical applications, exploration of oil minerals in geology, determination of soil mineral composition, and detection of trace elements in substances. LiSen Optics' fiber optic spectrometers feature interchangeable slits, selectable wavelength ranges, and resolution design, allowing customers to freely configure and match the fluorescence measurement system with suitable parameters according to their needs.

Fluorescence Measurement (Liquid)

Fluorescence Measurement (Powder, Solid)

Send Inquiry