Focus on spectral sensing and optoelectronic application systems

Research-Grade LIV Spectral-Power Characterization System

VCSEL (Vertical Cavity Surface Emitting Laser) technology is currently gaining more and more attention in applications such as face recognition system, 3D sensing, autonomous cars, gesture detection and VR (Virtual Reality)/AR (Augmented Reality)/MR (Mediated Reality), etc. Lisen Optics can provide customers with VCSEL-3D SENSING/TOF inspection solutions: LIV spectral/power integration test, near-field characteristics testing, far-field characteristics testing, BRDF/BTDF optical material AR/VR characteristics test, VCSEL special integrating sphere, to achieve the energy distribution and uniformity of VCSEL/LD monomer, module, and wafer chip. And other customized application requirements.

VCSEL (Vertical Cavity Surface Emitting Laser) technology is currently gaining more and more attention in applications such as face recognition system, 3D sensing, autonomous cars, gesture detection and VR (Virtual Reality)/AR (Augmented Reality)/MR (Mediated Reality), etc. Lisen Optics can provide customers with VCSEL-3D SENSING/TOF inspection solutions: LIV spectral/power integration test, near-field characteristics testing, far-field characteristics testing, BRDF/BTDF optical material AR/VR characteristics test, VCSEL special integrating sphere, to achieve the energy distribution and uniformity of VCSEL/LD monomer, module, and wafer chip. And other customized application requirements.

Product Introduction

The LS-VCS-SCI-LIV research-grade multifunctional LIV spectral power integration test system was developed by Lisen Optics specifically for 3D-SENSING based pulsed laser/LD laser LIV spectral testing, especially for wafer and module packaging users to use in the laboratory for VCSEL/LD research and development, to verify the VCSEL/LD photovoltaic process of each process characteristics of VCSEL/LD processes. It is used to verify the optoelectronic characteristics of VCSELs/LDs in various processes. It enables the measurement of LIV, EIV, TIE, PCE, spectral wavelength and power of VCSELs/LDs monoliths, modules and chips.

LS-VCS-SCI-LIV research grade multifunctional spectral power integration test system is specially developed for 3D-SENSING based pulsed laser, pulsed LD/LED test, which can be used for VCSEL, LD/LED photoelectric characteristics testing to ensure that VCSEL, LD/LED pulsed laser radiation spectrum to meet the device optical function and IEC-60825-2 laser safety - human eye safety application requirements.

The LS-VCS-SCI-LIV research-grade multifunctional LIV spectral power integration test system was developed by Lisen Optics specifically for 3D-SENSING based pulsed laser/LD laser LIV spectral testing, especially for wafer and module packaging users to use in the laboratory for VCSEL/LD research and development, to verify the VCSEL/LD photovoltaic process of each process characteristics of VCSEL/LD processes. It is used to verify the optoelectronic characteristics of VCSELs/LDs in various processes. It enables the measurement of LIV, EIV, TIE, PCE, spectral wavelength and power of VCSELs/LDs monoliths, modules and chips.

LS-VCS-SCI-LIV research grade multifunctional spectral power integration test system is specially developed for 3D-SENSING based pulsed laser, pulsed LD/LED test, which can be used for VCSEL, LD/LED photoelectric characteristics testing to ensure that VCSEL, LD/LED pulsed laser radiation spectrum to meet the device optical function and IEC-60825-2 laser safety - human eye safety application requirements.

Main Functional Features

● Powerful special software analysis function, can scan and measure LIV curve, PCE curve, temperature-peak wavelength-optical power curve, can set scanning accuracy and speed, can measure photoelectric conversion efficiency, automatically save test data.

● High precision spectrometer spectral ranges 200-1700nm optional, spectral resolution 0.1nm (800-1000nm), to achieve peak wavelength and FWHM measurement, the fastest 2kHz sampling rate, can scan the measurement of temperature - peak wavelength - power curve, etc.

● Manual or fully automated probe stage for automated LIV spectral power testing of wafers or modules.

● Precise temperature control of samples, settable scan steps, high-speed simultaneous triggering, preset/custom measurements.

● Multi-thread linkage (high-power high-precision current source, high-precision high-speed digital multimeter, multi-channel synchronous digital multimeter, power detector, spectrometer, temperature controller, etc.) can realize programmed and automated scanning measurement of spectra, power, current, temperature and other parameters.

● Integrated industrial control chassis, high-resolution LCD display, automated integrated operation software.

● Adopt four-line measurement method, real-time record of measured current, voltage value, power value, more accurate test

● Program can be set to continuous and pulse scanning mode.

● Life aging detection function (optional): Under constant or pulsed conditions (current, temperature), spectral and power data are recorded at specified time intervals.

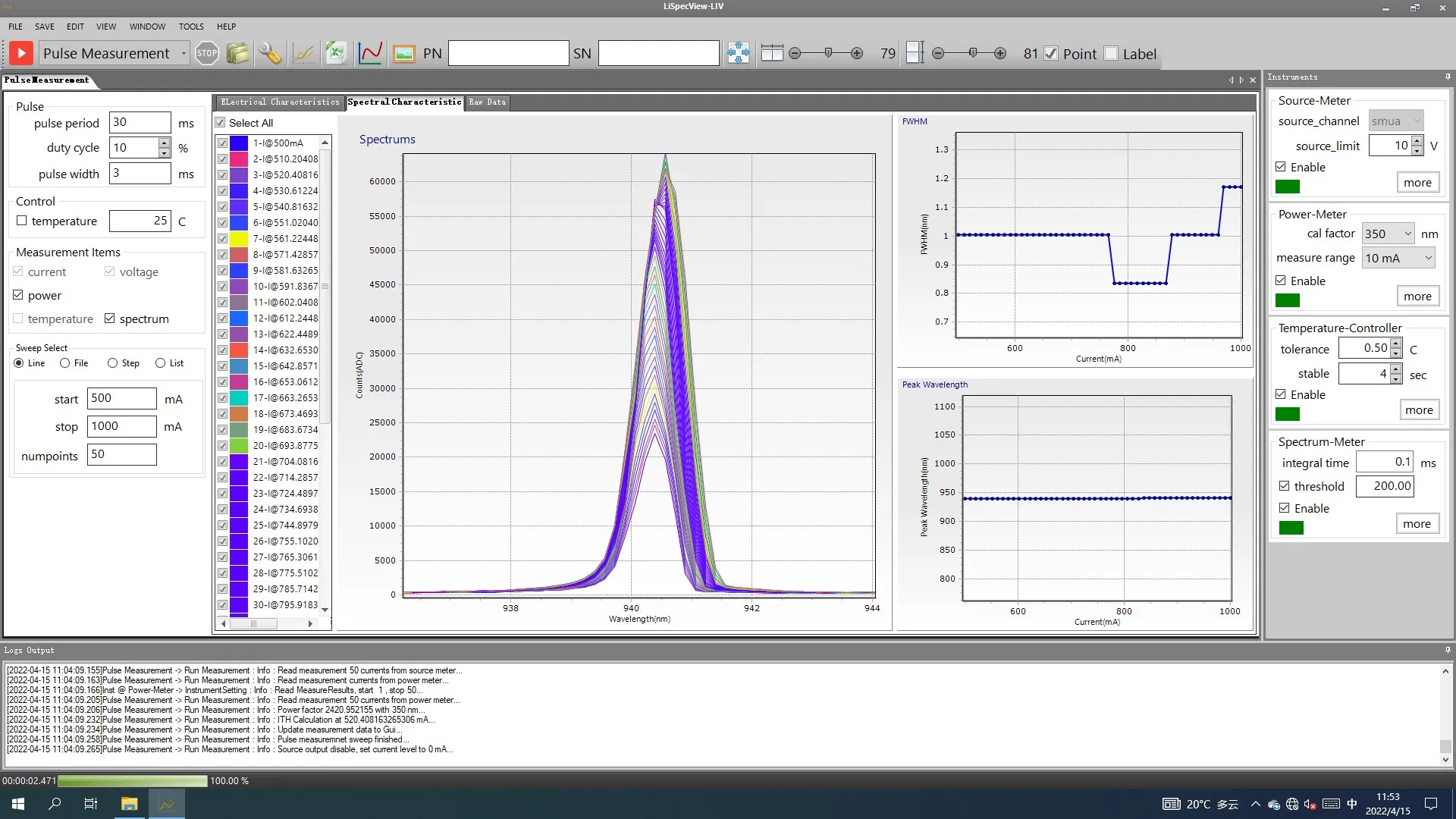

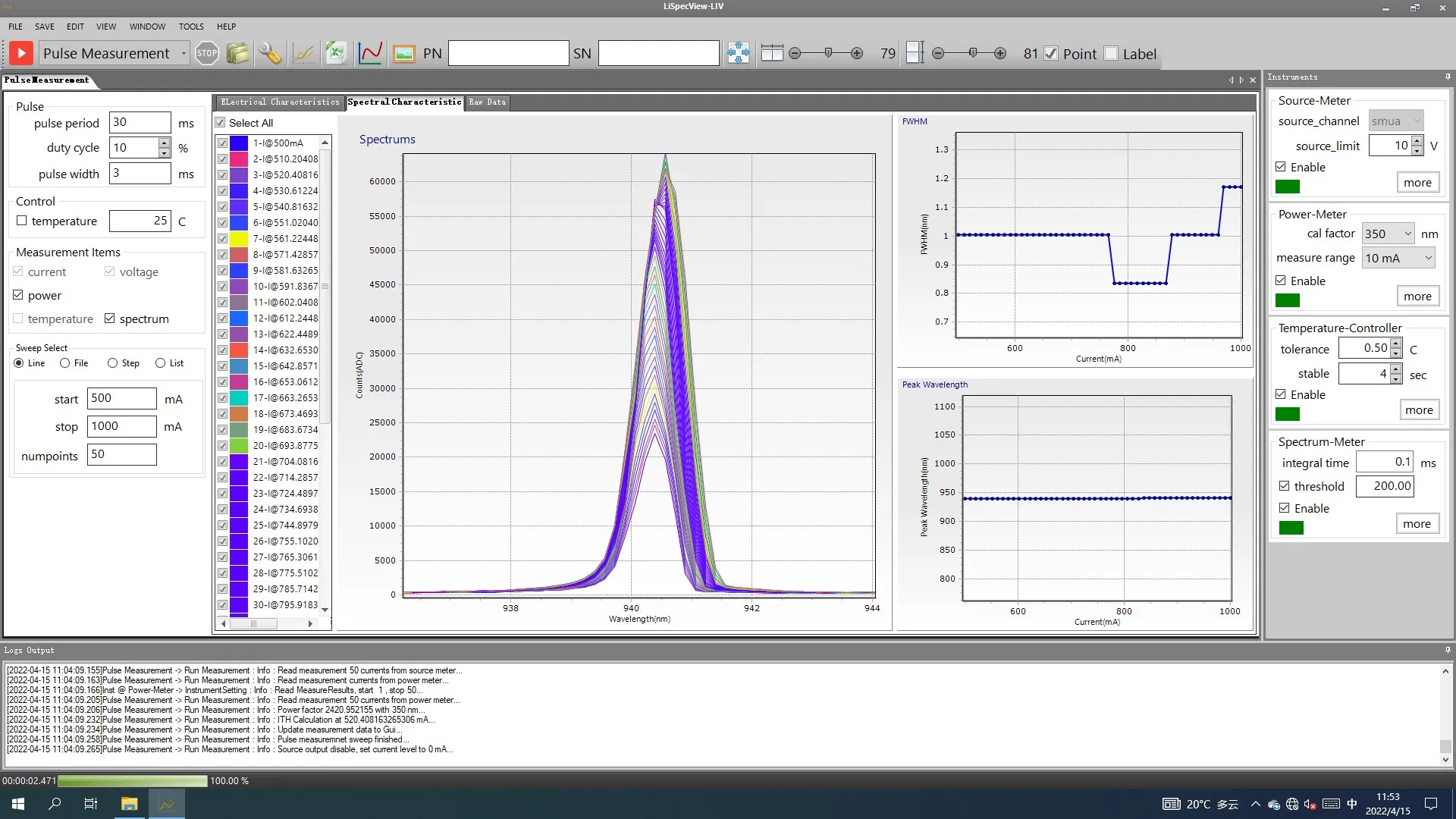

Spectral Demonstrate Software’s UI

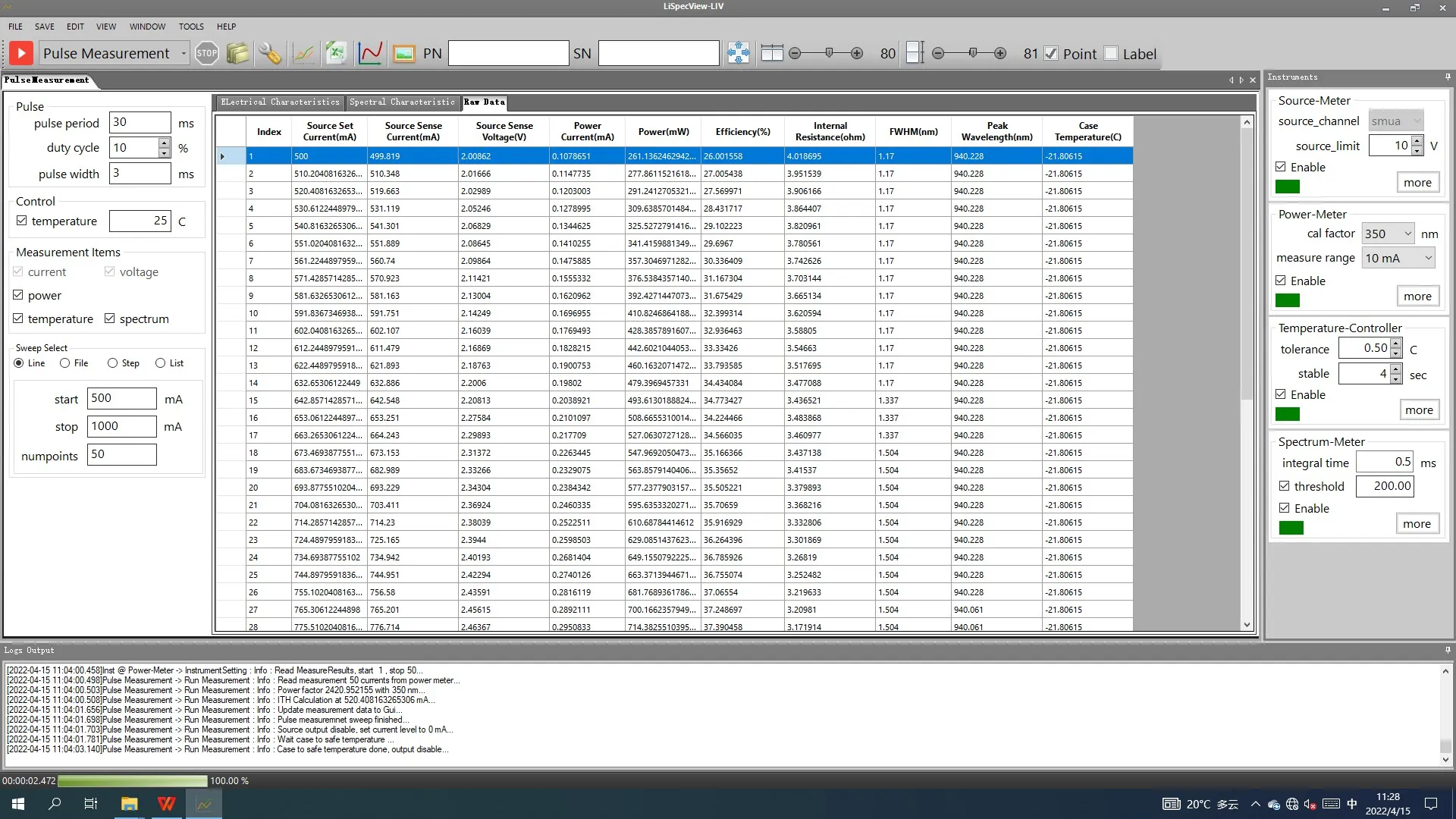

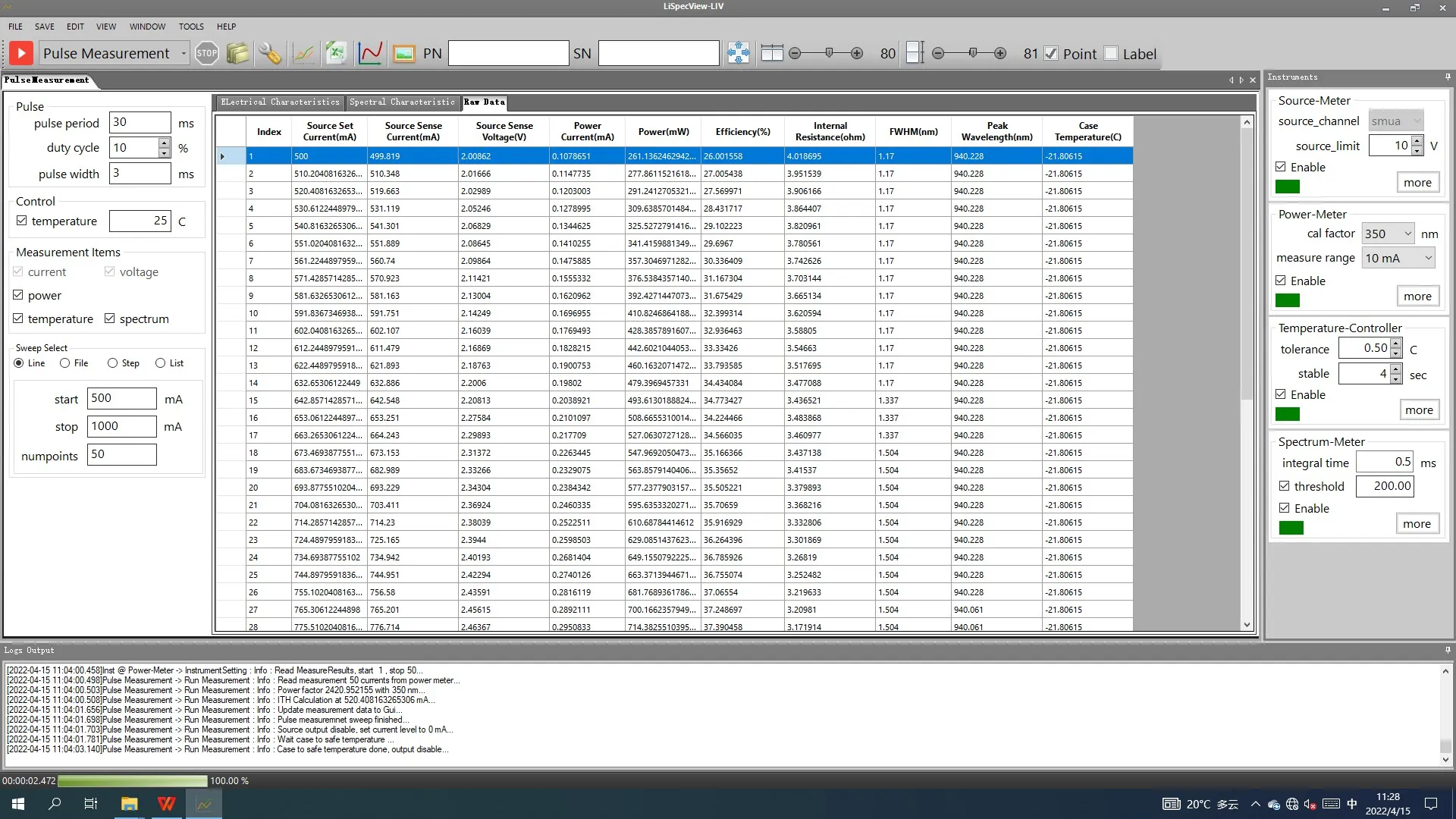

Test Data

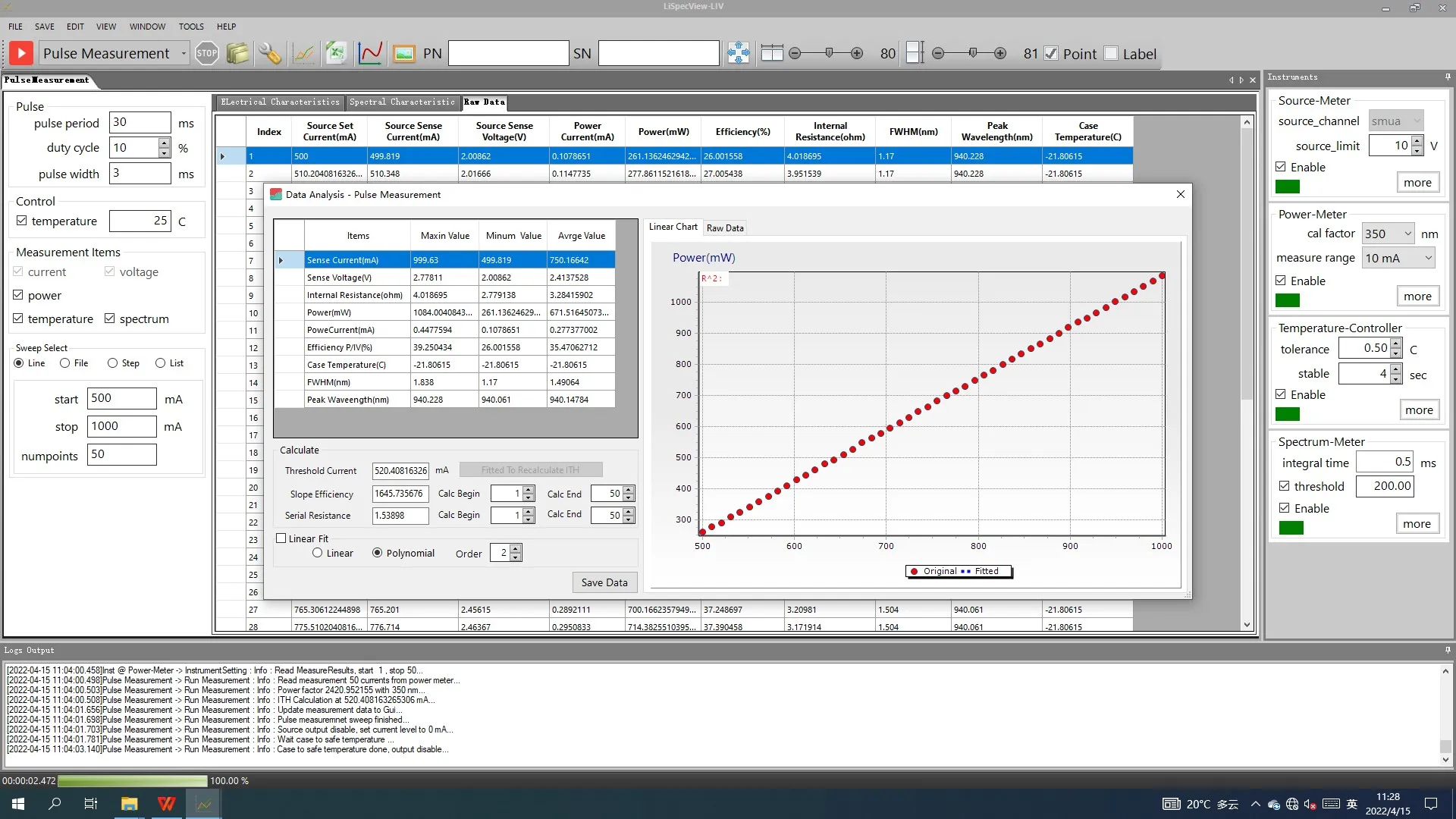

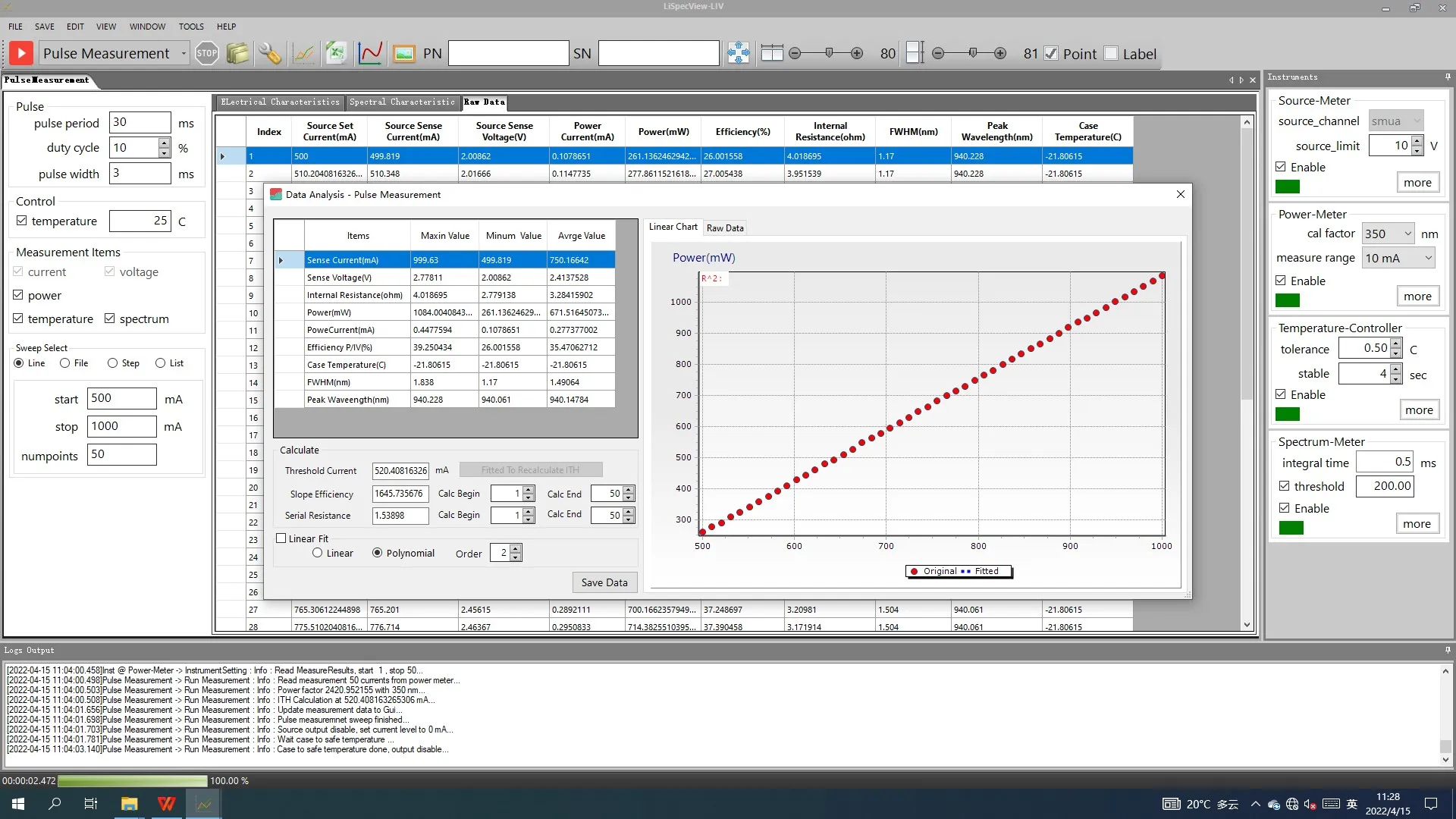

Data Analysis’s UI

Main Functional Features

● Powerful special software analysis function, can scan and measure LIV curve, PCE curve, temperature-peak wavelength-optical power curve, can set scanning accuracy and speed, can measure photoelectric conversion efficiency, automatically save test data.

● High precision spectrometer spectral ranges 200-1700nm optional, spectral resolution 0.1nm (800-1000nm), to achieve peak wavelength and FWHM measurement, the fastest 2kHz sampling rate, can scan the measurement of temperature - peak wavelength - power curve, etc.

● Manual or fully automated probe stage for automated LIV spectral power testing of wafers or modules.

● Precise temperature control of samples, settable scan steps, high-speed simultaneous triggering, preset/custom measurements.

● Multi-thread linkage (high-power high-precision current source, high-precision high-speed digital multimeter, multi-channel synchronous digital multimeter, power detector, spectrometer, temperature controller, etc.) can realize programmed and automated scanning measurement of spectra, power, current, temperature and other parameters.

● Integrated industrial control chassis, high-resolution LCD display, automated integrated operation software.

● Adopt four-line measurement method, real-time record of measured current, voltage value, power value, more accurate test

● Program can be set to continuous and pulse scanning mode.

● Life aging detection function (optional): Under constant or pulsed conditions (current, temperature), spectral and power data are recorded at specified time intervals.

Spectral Demonstrate Software’s UI

Test Data

Data Analysis’s UI

Main Technical Indicators

|

Model |

LS-VCS-SCI-LIV |

|

Wavelength Range |

200~1700nm(Optional) |

|

Optical Power |

0~50W(Higher Power Optional) |

|

Spectral Resolution |

0.1nm(800~1000nm) |

|

Photoelectric Conversion Efficiency |

0~100% |

|

Integrating Sphere |

1" / 2" / 3.3" / 4" / 5" / 6" / 8 |

|

Operating Voltage |

0~35V,3A@6V |

|

Operating Current |

DC Current:±100pA~±3.03A;Pluse Current:0~±10A |

|

Threshold Current |

Yes |

|

Slope Efficiency |

Yes |

|

Resistance (Internal Resistance) |

Yes |

|

PD Dark Current |

1pA~100nA |

|

PD Light Current |

0~100mA |

|

Optical Power-PD Current Curve |

LIV Characteristic Curve |

|

QCW / CW |

DC adjustable / PWM adjustable |

|

Pulse Time |

3A@6V, Minimum pulse width 0.15ms |

|

Probe Station |

Optional |

|

Duty Cycle |

0~100% |

|

Temperature Control Range |

5℃~85℃@ Precision ±1℃ |

|

Size / Weight |

37cm×52cm×41cm,25kg |

Main Technical Indicators

|

Model |

LS-VCS-SCI-LIV |

|

Wavelength Range |

200~1700nm(Optional) |

|

Optical Power |

0~50W(Higher Power Optional) |

|

Spectral Resolution |

0.1nm(800~1000nm) |

|

Photoelectric Conversion Efficiency |

0~100% |

|

Integrating Sphere |

1" / 2" / 3.3" / 4" / 5" / 6" / 8 |

|

Operating Voltage |

0~35V,3A@6V |

|

Operating Current |

DC Current:±100pA~±3.03A;Pluse Current:0~±10A |

|

Threshold Current |

Yes |

|

Slope Efficiency |

Yes |

|

Resistance (Internal Resistance) |

Yes |

|

PD Dark Current |

1pA~100nA |

|

PD Light Current |

0~100mA |

|

Optical Power-PD Current Curve |

LIV Characteristic Curve |

|

QCW / CW |

DC adjustable / PWM adjustable |

|

Pulse Time |

3A@6V, Minimum pulse width 0.15ms |

|

Probe Station |

Optional |

|

Duty Cycle |

0~100% |

|

Temperature Control Range |

5℃~85℃@ Precision ±1℃ |

|

Size / Weight |

37cm×52cm×41cm,25kg |

Prev: no data!

Send Inquiry